本文介绍阳极氧化的后处理工艺流程、优势,并概述了可选的着色方法。 阳极氧化是一项用于表面处理的后处理工艺。该工艺属于转化镀层方法,可使铝材和其他适用金属表面形成一层氧化膜。这一电化学反应会使金属零件表面自然形成的氧化层变厚。

不同于单纯在表面增加涂层的喷漆工艺,阳极氧化工艺使氧化层与基体材料完全结合,因此不会产生剥落现象。该氧化层具有高度规则的多孔结构,便于后续进行着色、封孔等加工处理。铝材是阳极氧化工艺的首选材料。但也可以对镁、钛等其他金属进行阳极氧化处理。

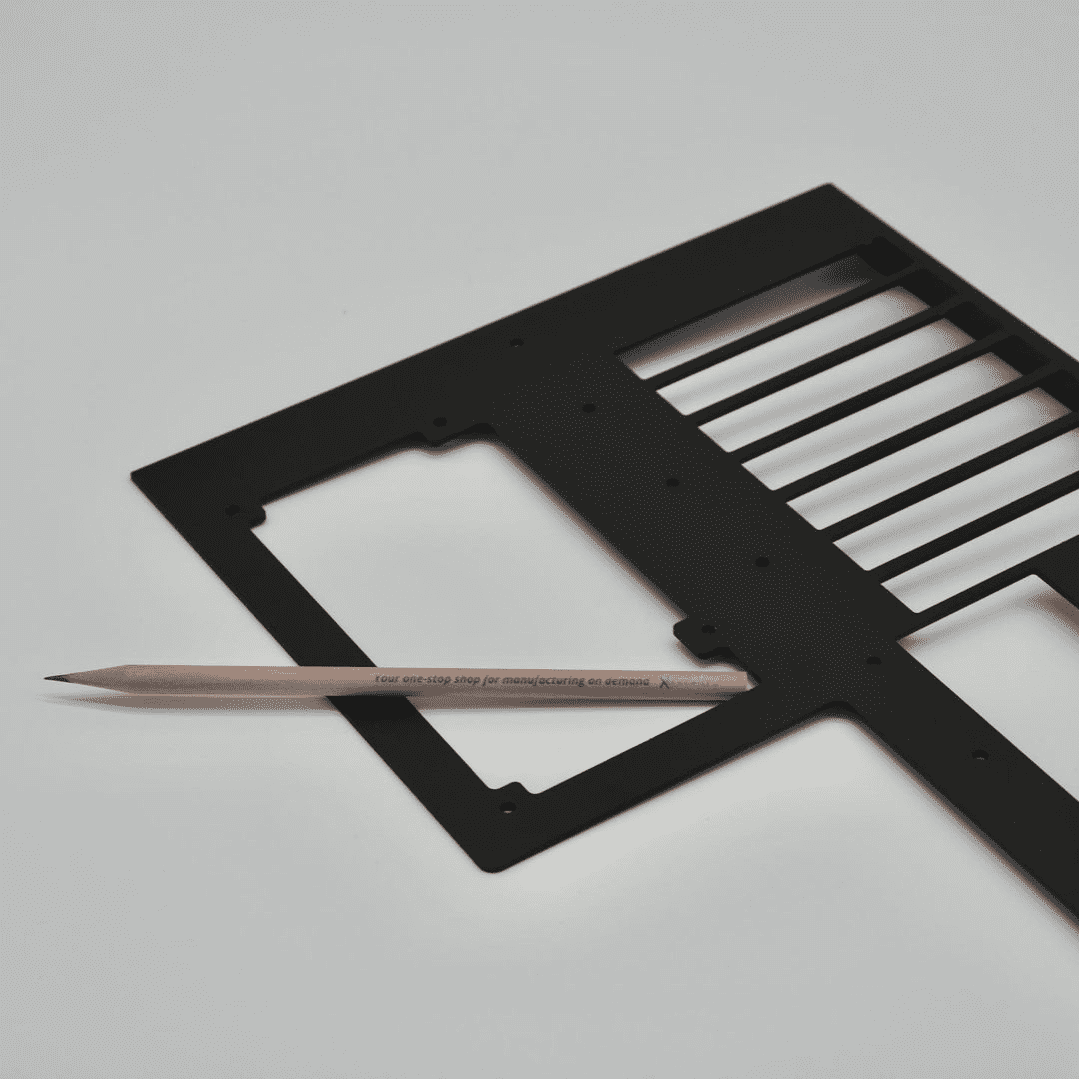

阳极氧化通常被用作 CNC 加工和钣金制造零件的表面处理工艺。该工艺简单高效,可显著提升零件的耐用性、耐磨性、硬度与抗腐蚀性。该工艺还能提升美观度,使零件表面呈现光泽,并支持多种颜色选择。

阳极氧化工艺:一种高效的铝材表面处理工艺

本文介绍阳极氧化的后处理工艺流程、优势,并概述了可选的着色方法。 阳极氧化是一项用于表面处理的后处理工艺。该工艺属于转化镀层方法,可使铝材和其他适用金属表面形成一层氧化膜。这一电化学反应会使金属零件表面自然形成的氧化层变厚。

不同于单纯在表面增加涂层的喷漆工艺,阳极氧化工艺使氧化层与基体材料完全结合,因此不会产生剥落现象。该氧化层具有高度规则的多孔结构,便于后续进行着色、封孔等加工处理。铝材是阳极氧化工艺的首选材料。但也可以对镁、钛等其他金属进行阳极氧化处理。

阳极氧化通常被用作 CNC 加工和钣金制造零件的表面处理工艺。该工艺简单高效,可显著提升零件的耐用性、耐磨性、硬度与抗腐蚀性。该工艺还能提升美观度,使零件表面呈现光泽,并支持多种颜色选择。

阳极氧化工艺:具体操作步骤是什么?

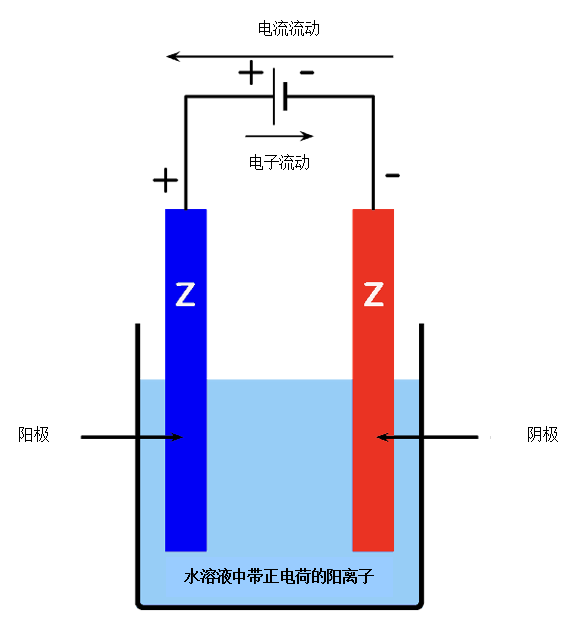

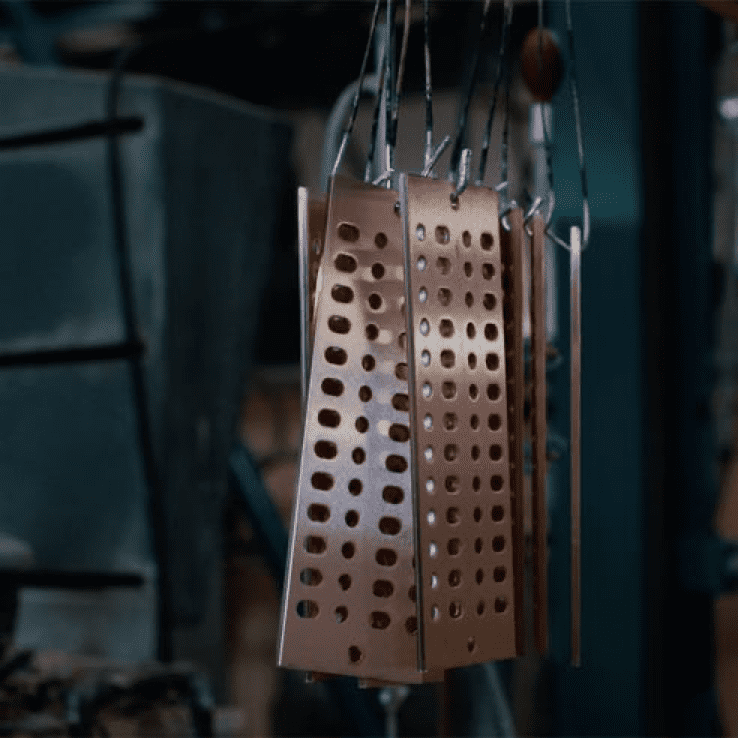

阳极氧化通过电解槽电化学工艺实现。将待阳极氧化的铝件彻底清洗,去除杂质后,完全浸没于酸性电解槽中。将阴极固定在阳极氧化槽中。铝材浸入后即充当阳极。

在阳极和阴极间通入直流电流后,电解槽中产生的氧离子会向铝件迁移,并与铝原子结合,生成氧化铝。由此,零件表面会形成一层阳极氧化阻隔层。

该工艺会改变金属表面的微观纹理及表层附近基体金属的晶体结构。钛夹具架和铅阴极是铝材阳极氧化最常用的阴极配置。

阳极氧化工艺按电解液差异可分为三类:

- 第 I 类 ——铬酸阳极氧化:第 I 类采用铬酸电解液。铬酸阳极氧化生成的膜层厚度约为 0.00254 毫米,且在染色时颜色附着性最差。由于耐磨性欠佳且孔隙率较低,该工艺并不常用。

- 第 II 类 ——硫酸阳极氧化:基于硫酸的 II 类阳极氧化工艺可形成约 0.00508-0.0254 毫米厚的氧化膜,具备良好的着色性能。其展现出良好的耐腐蚀与耐磨特性。

- 第 III 类 ——硬质阳极氧化: 第 III 类工艺虽然也使用硫酸,但处理温度显著降低。硬质阳极氧化处理能够产生厚度为 0.0508-0.1524 毫米的氧化膜,属于三类工艺中最厚的一种。硬质阳极氧化处理的零件具有极好的耐磨性和抗腐蚀性,且氧化膜孔隙率最高。另一类被称为建筑用阳极氧化的工艺,主要利用金属离子的特性。

可用于阳极氧化的材料

阳极氧化工艺仅适用于可导电的材料。铝是最常用材料。镁、钛等有色金属也可进行阳极氧化处理。其它适用的材料包括锌、铌、锆、铪和钽等。黑色金属可通过硝酸或红烟硝酸实现阳极氧化。处理后将产生质地坚硬、分布均匀的黑色氧化铁 (II、III)。由于在处理过程中容易发生腐蚀,钢和其他黑色金属不适合进行阳极氧化处理。

阳极氧化工艺优势

阳极氧化工艺主要具有以下优势:

- 优异的表面性能:阳极氧化工艺可提升材料的表面性能。它提升了零件的抗刮擦、抗腐蚀和耐磨性能

- 提升防护等级:阳极氧化的保护层与零件紧密结合,不会剥落或碎裂,因此提供的防护优于喷漆工艺

- 更好的镀层附着力:氧化层提升了表面附着力,使得油漆底漆和胶水在阳极氧化金属表面的附着力比裸金属更强

- 防止金属咬合:阳极氧化可防止螺栓、螺母等螺纹零件出现咬合问题(滑动表面粘着导致的磨损)

- 光亮表面质感:阳极氧化工艺可使表面呈现光亮质感。同时,该工艺还可以实现零件的多样化着色

- 优异的绝缘性能:该工艺可改善绝缘性能,因为处理后的零件电导率低于裸金属。

彩色阳极氧化

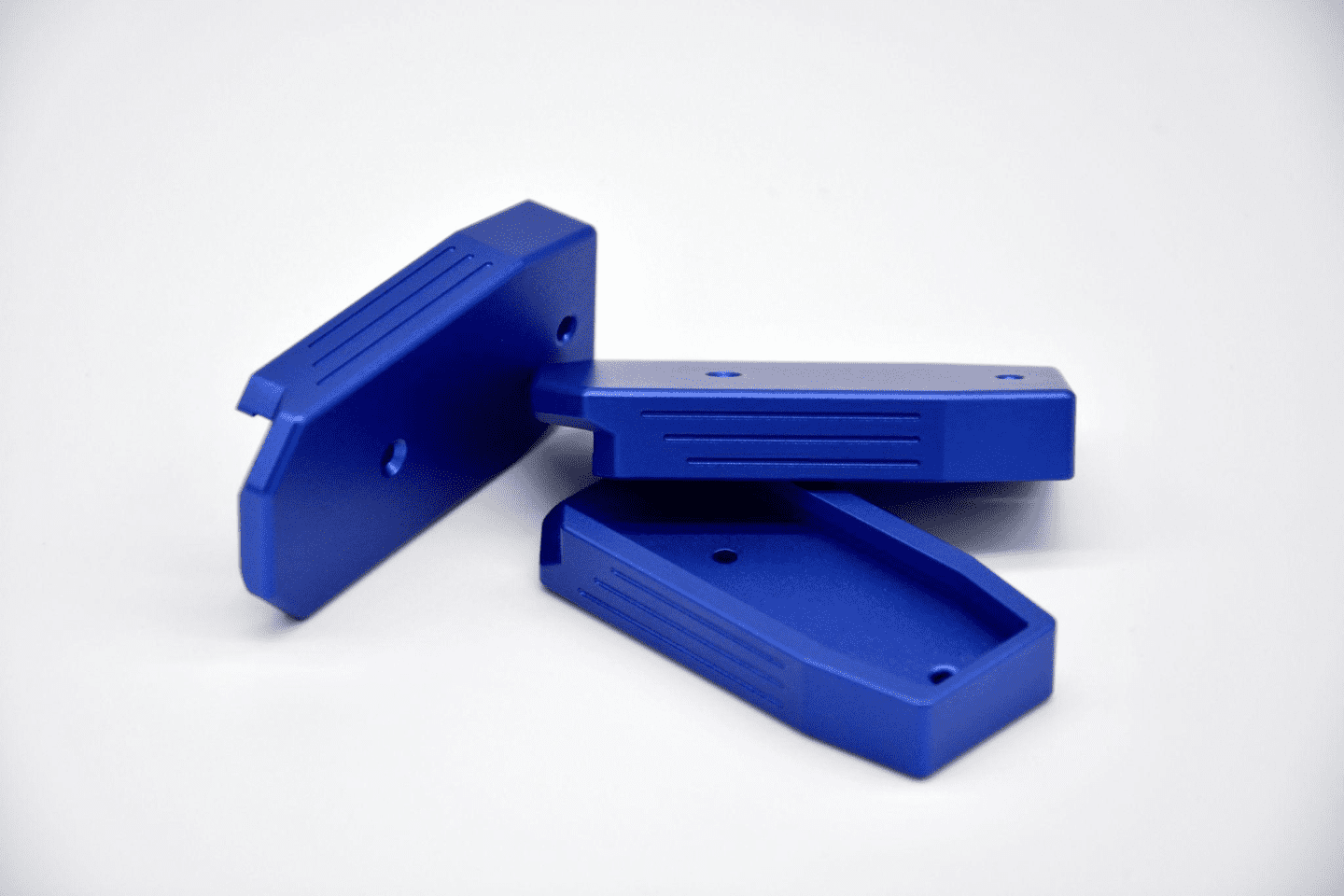

阳极氧化零件的标准颜色包括透明、青铜、香槟色和黑色。其他颜色包括红色、粉色、金色、黄色、绿色、棕色、黑色、蓝色、紫色、橄榄绿和灰色。但黑色是最常见的颜色,其次是蓝色、红色和金色。

染色

阳极氧化零件可以是染色的,也可以保持原色。零件在阳极氧化完成后会直接浸入热染槽中。该工艺可实现多种颜色效果。

电解着色

电解着色是另一种为阳极氧化零件染色的方法。处理时需将零件和金属盐同时浸入另一电解溶液中。这些金属盐会形成具有抗紫外线特性的镀层。但能够实现的颜色只有黑色和古铜色两种。

颜色选择

选择阳极氧化零件颜色时,一般可参照颜色名称或 RAL 编码。颜色名称通过直接使用名称来指定常见的颜色,如绿色、红色等。这是进行阳极氧化颜色选择时最常见的方式。

大型生产企业可提供基于 RAL 色卡系统的阳极氧化,以实现精准匹配所需颜色。RAL 色彩系统可区分特定颜色的不同色调和类型,从而提供丰富的色彩选择范围。例如,颜色名称可能仅简单标注为“灰色”,而 RAL 色卡则会明确标注为“煤灰色”,对应色号“RAL 7016”,同时还提供多种不同类型的灰色选项。

总结

Xometry择幂科技可为我们的所有镁件和铝件提供高品质的硬质及彩色阳极氧化处理。我们提供包括黑色、蓝色、金色、绿色、红色、橙色等多种颜色选择。如有阳极氧化需求,只需在上传模型至实时报价引擎,选定所需的表面处理类型和颜色。若对适用您应用的阳极氧化工艺选择有疑问,欢迎随时联系我们的专家获取帮助。