近年来,3D 打印作为一种迅速崛起的制造技术,不仅在工业领域得到日益广泛的应用,还逐渐成为业余爱好者和发烧友工作流程中的重要组成部分。本文介绍了 10 个兼具趣味性与挑战性的 DIY 开源项目构想,助您充分发挥 3D 打印技术的强大能力。

1. OpenRC 一级方程式玩具车

这一完全开源的遥控玩具一级方程式赛车 3D 打印项目,让您和您的打印机在竞赛中一展身手。这一社区趣味项目吸引了众多参与者,他们在其中交流各种改装方案、教程和见解。可根据您需要的规格修改,并按所需尺寸完成打印(最大长度可达 150 厘米以上)。 作为学习遥控系统的理想之选,Open RC F1 让您和您的打印机在赛道上一展身手。以下内容详细介绍了如何构建和组装 3D 打印汽车。

欲了解更多信息,请访问:https://danielnoree.com/the-openrc-f1-build-guide/

相关设计文件请访问::https://www.thingiverse.com/thing:1193309

推荐的材料与制造工艺:推荐使用坚固耐用的 ABS 材料,并采用经济高效的 FDM 和 MJF 等工艺。

2. 蜻蜓科技

这款 3D 打印蜻蜓是打发空闲时间的极佳开源项目。这款小巧的装置从蜻蜓非凡的飞行力学原理中获得了启发。机翼的动力来源是缠绕的橡皮筋。该项目致力于加深爱好者对飞行特性的了解。您可以通过下方链接查看项目的设计文件和详情。 .

欲了解更多信息,请访问: https://www.thingiverse.com/thing:951687

https://youtu.be/r8CszYNxGHg

推荐的材料与制造工艺:推荐使用轻便灵活的 PP 或 PLA 材料,并采用经济耐用的 FDM 和 MJF 等工艺。

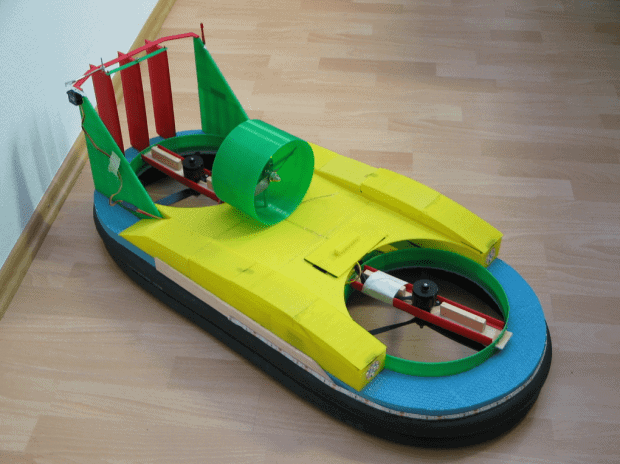

3.气垫船

该 DIY 项目最初是学生的基础项目,旨在作为打造北极廉价移动科考站气垫船的初步尝试。作为重要的 3D 打印项目,其大部分组件均由 3D 打印完成。但底座部分是采用切割泡沫塑料制作的。

欲了解更多信息,请访问:https://makezine.com/projects/3d-print-rc-hovercraft/

相关设计文件请访问:https://www.thingiverse.com/thing:901976

推荐的材料与制造工艺:推荐使用 ABS 材料,以打造结实耐用的结构,可采用 FDM 或 MJF工艺。

4. DIY 四轴飞行器

此款 3D 打印 FPV 四轴飞行器重量轻,采用防摔设计,可有效保护机载设备。尽管该 3D 打印项目成本较高,但在 Thingiverse 上有多达 24 种设计选项,可满足不同预算需求。您可以通过下方链接查看项目介绍和相关资料。

欲了解更多信息,请访问: https://www.instructables.com/Micro-105-FPV-Quadcopter-3D-Printed/

相关设计文件请访问: https://www.thingiverse.com/thing:1221911

推荐的材料与制造工艺:尽管 PLA 材料可用,但 ABS 材料在防摔性能方面表现更佳。如照片所示,其顶部采用 PLA 材料打印,底部则为 ABS 材料。 推荐采用FDM 或 MJF 工艺。

5. Strandbeest——沙滩兽

Strandbeest 是一款集工程技术与艺术于一身的炫酷 3D 打印动感雕塑。它们依靠风力,在荷兰海滩上缓缓游荡。你可以亲手打造属于自己的 DIY Strandbeest,享受乐趣。Strandbeest 由八个单独的组件构成,且通过依次反复组装而成。

欲了解更多信息,请访问: https://www.instructables.com/3D-Printed-Theo-Jansen-Strandbeest/

https://youtu.be/nLyx7FADO4s

推荐的材料与制造工艺:推荐使用价格低廉且适合灵活可动部件的尼龙材料。 制造工艺可根据成本选择 MJF、FDM 或 SLS。

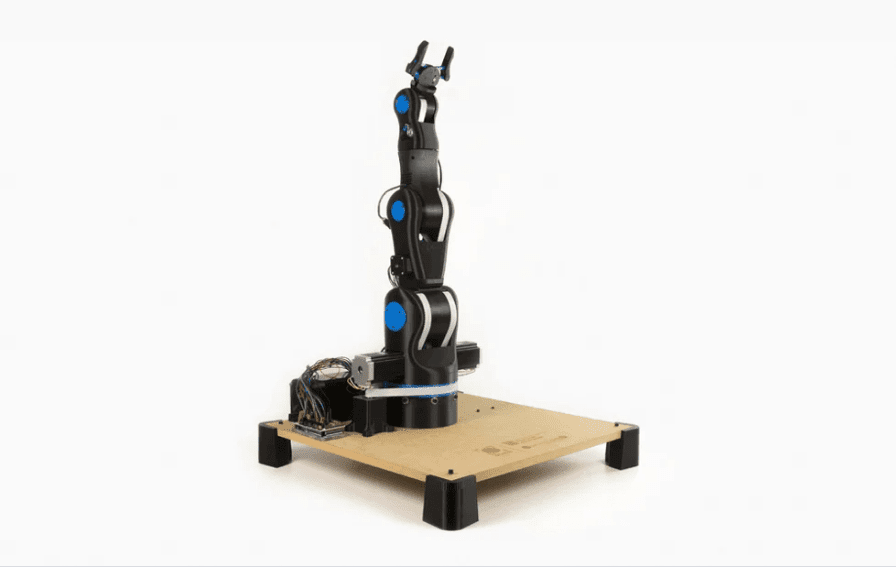

6. 机械臂

五轴机械臂是另一个趣味十足且难度颇高的开源项目。由专业工程师团队开发,可通过 3D 打印完成多个部件的制作。它不仅使用打印的部件,还需要步进电机和 Arduino。该机械臂搭载了专为机器人研发的 Zortrax 步进电机。

欲了解更多信息并查看设计文件,请访问:https://www.thingiverse.com/thing:1693444

推荐的材料与制造工艺:PLA 和 PC 是打造高强度、功能性部件的理想材料。就本项目而言,FDM 工艺是最优且经济实惠的选择。

7. 自动吸水花盆

旅行在外,无法给植物浇水怎么办?无需纠结,即刻动手打印您的解决方案。这款简易的 3D 打印设计让需要频繁浇水的植物养护变得更简单。您只需一个装满水的普通玻璃罐。将 3D 打印的花盆与土壤、植物(种子或树苗)一并置于罐上。为需要排水的植物留出排水空间。这样做的好处是,透明的玻璃罐让水位一目了然。

欲了解更多信息并查看设计文件,请访问: https://www.thingiverse.com/thing:4683066/files

推荐的材料与制造工艺:PETG 是最适用于打印防水防潮组件的塑料材料。因为所需丝材容易获取,它也适合采用 FDM 工艺打印。

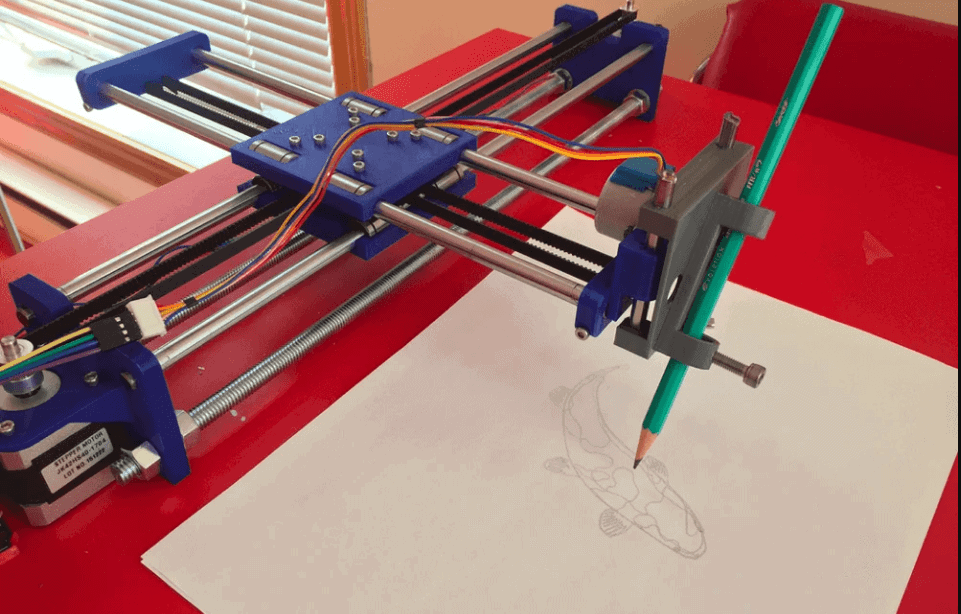

8. 绘图机

绘图机是制作贺卡和正式邀请函等物品的理想工具。这款部分采用 3D 打印技术的绘图机,让工作过程变得既轻松又愉悦。可夹持任何笔具,并通过栅格文件创作精美的作品和炫酷的纸质艺术。

欲了解更多信息并查看设计文件,请访问:https://www.thingiverse.com/thing:1514145

推荐的材料与制造工艺:此用途适合使用高强度材料如 ABS、PC 和 PLA,工艺可选择FDM 或 MJF。

9. PiKon 望远镜

您是否对观星感兴趣?如果是的话,这个酷炫的项目正适合您。PiKon 望远镜通过 3D 打印制造,搭载树莓派系统,让您能在屏幕上观赏星空,且所用组件的成本更低。

欲了解更多信息并查看设计文件,请访问:https://www.instructables.com/PiKon-Telescope/

推荐的材料与制造工艺:该项目主要使用 PVC 管作为望远镜镜筒,其他组件也可采用 PLA 制作,以兼顾耐用性和经济性。推荐采用FDM 或 MJF 工艺。

10. DIY 相机滑轨

对于摄影师来说,优质设备的购置成本通常相当高昂。这款电机驱动相机滑轨的 3D 打印项目,生动展示了 3D 打印在制造消费者所需且价格亲民的物品方面的出色表现。其采用 PVC 管作为滑轨,并使用直流电机驱动。

欲了解更多信息并查看设计文件,请访问: https://www.instructables.com/3D-Printed-Camera-Slider-Motorized/

推荐的材料与制造工艺:尼龙或 PLA 是制作这些塑料部件的最经济选择,而 FDM 和 MJF 工艺成本较低,同时支持多色丝材打印。

访问Xometry择幂科技实时报价系统获取报价并订购您的 3D 打印产品!