Materials

Aluminium;Steel;Stainless steel;Copper;Titanium;Polymer;Nylon ;PC .All these materials are available in the Xometry Instant Quoting Engine. If you require a different, material please specify it as custom when you make a request.

Aluminium 3.4365

Alternative Designations: EN-AW7075 | Al-Zn6MgCu

Aluminium 3.4365/EN-AW7075 has high strength (57MPa), toughness and excellent resistance to fatigue. It has very good machinability.

Aluminium 3.3211

Alternative Designations: EN-AW6061 | Al-Mg1SiCu

Aluminium 3.3211/EN-AW6061 contains magnesium and silicon as its major alloying elements with trace amounts of copper.

Aluminium 3.3206

Alternative Designations: EN-AW6060 | Al-MgSi

Aluminium 3.3206/EN-AW6060 has good resistance to corrosion, good weldability and very suitable for cold forming.

Aluminium 3.2315

Alternative Designations: EN-AW6082 | Al-Si1Mg

Typically formed by rolling and extrusion, Aluminium 3.2315 has medium strength with very good weldability and thermal conductivity.

Aluminium 3.1645

Alternative Designations: EN AW–2007 | 3.1645 | AlCuMgPb

Aluminium 3.1645 is a short chipped aluminum alloy containing between 4.0 – 5.0% copper. It is very suitable for high machining speeds.

Steel 1.0570

Alternative Designations: St52-3

Compared to other carbon steels, Steel 1.0570 has high electrical conductivity but low thermal conductivity and low ductility.

Steel 1.0503

Alternative Designations: AF65C45

Steel 1.0503 (C45) has low thermal conductivity and low ductility among wrought carbon steels. It has a high tensile strength of 630MPa.

Steel 1.7225

Alternative Designations: 42CrMo4

Steel 1.7225 has high strength, toughness, good hardenability and resistance to impact. It is widely used in the construction of machines

Steel 1.7131

Alternative Designations: 16MnCr5

Steel 1.7131 has high surface hardness and wear resistance with good machinability. It is ideal for machine components.

Steel 1.0038

Alternative Designations: EN 10025 | S235JR

Steel 1.0038 can be formed into many products. Its excellent weldability makes it to be widely used in bridges, transmission towers etc.

Stainless Steel 17-4PH / 1.4542 / X5CrNiCuNb16-4

Alternative Designations: Stainless Steel 17-4PH / 1.4542 / X5CrNiCuNb16-4

Stainless Steel 316L / 1.4404 / X2CrNiMo17-12-2

Alternative Designations: Stainless Steel 316L / 1.4404 / X2CrNiMo17-12-2

Stainless Steel 304 / 1.4301 / X5CrNi18.10

Alternative Designations: Stainless Steel 304 / 1.4301 / X5CrNi18.10

Stainless Steel 303 / 1.4305 / X10CrNiS18-9

Alternative Designations: Stainless Steel 303 / 1.4305 / X10CrNiS18-9

Stainless Steel 1.4571

Alternative Designations: X6CrNiMoTi17-12-2

Stainless Steel 1.4571 contains a small amount of titanium (about 0.5%). It has good machinability but cannot be hardened by heat treatment.

Stainless Steel 1.4301

Alternative Designations: X5CrNi18.10

Stainless steel 1.4301 is chromium-nickel austenitic stainless steel. The chromium element gives it excellent corrosion resistance.

Copper 2.0065

Alternative Designations: E-Cu58Ms58

Copper 2.0065 has high electrical conductivity. Its good machinability makes it easy to shape into different forms.

Copper 2.0060

Alternative Designations: Cu-ETP

Copper 2.0060 has high conductivity and high corrosion resistance. It has a tensile strength of 360MPa. It has excellent machinability.

Brass 2.0401

Alternative Designations: CuZn39Pb3

Brass 2.0401 has excellent hot formability and can easily be soldered or brazed. It has very good free-cutting.

Titanium 3.7164

Alternative Designations: Titan Grade 5 | 6Al-4V9

Titanium 3.7164 has exceptional strength compared to pure titanium but retains the same stiffness and thermal properties.

Titanium 3.7035

Alternative Designations: Titan Grade 2

Titanium 3.7035 has excellent strength-to-weight ratio with good resistance to corrosion. Its thermal stresses are low.

UHMW PE

Alternative Designations: Ultra high molecular weight polyethylene

UHMW PE is extremely tough and has high resistance to abrasion and wear. It is corrosion resistant and self-lubricating.

PTFE

Alternative Designations: Teflon

PTFE (Teflon) is a highly slippery material with excellent resistance to extreme temperatures. It has outstanding insulating properties.

POM

Alternative Designations: Delrin, Acetal

POM is an easy resin for molding. It has a relatively high tensile strength as well as high resistance to wear, creep and warp.

Acrylic

Alternative Designations: PMMA

Acrylic (PMMA) is the most common form of clear, moldable thermoplastic, often used in place of glass due to its higher resistance.

PC

Alternative Designations: Polycarbonate

PC – Polycarbonate is a naturally transparent plastic with high strength and durability on impact. It is shatter resistant and heat resistant.

ABS

Alternative Designations: Acrylonitrile Butadiene Styrene

ABS (Acrylonitrile Butadiene Styrene) is a thermoplastic material widely known for its high resistance to impact and toughness.

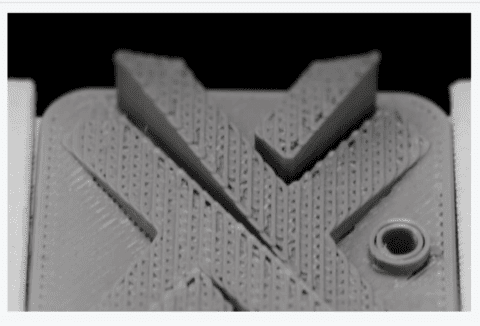

PA2200-SLS

Alternative Designations: PA2200-SLS

HT200 thermal-resistant resin-PuSL (micrometer)

Alternative Designations: HT200 thermal-resistant resin-PuSL (micrometer)

RGD series of materials-Polyjet (Color)

Alternative Designations: RGD series of materials-Polyjet (Color)

Nylon PA 12 Glass-Filled-MJF

Alternative Designations: Nylon PA 12 Glass-Filled-MJF

HTL thermal-resistant resin-PuSL (micrometer)

Alternative Designations: HTL thermal-resistant resin-PuSL (micrometer)

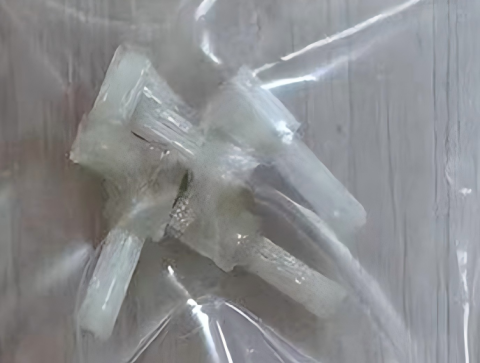

BIO biocompatible resin-PuSL (micrometer)

Alternative Designations: BIO biocompatible resin-PuSL (micrometer)

Tough toughened material-PuSL (micrometer)

Alternative Designations: Tough toughened material-PuSL (micrometer)

ST1400 toughened material-PuSL (micrometer)

Alternative Designations: ST1400 toughened material-PuSL (micrometer)

RGB200 series of materials-WJP (Color)

Alternative Designations: RGB200 series of materials-WJP (Color)

Zirconia ceramic printing-DLP

Alternative Designations: Zirconia ceramic printing-DLP

Alumina ceramic printing-DLP

Alternative Designations: Alumina ceramic printing-DLP

Red wax resin-DLP

Alternative Designations: Red wax resin-DLP

RG9400 B FR-DLP

Alternative Designations: RG9400 B FR-DLP

RG3280-DLP

Alternative Designations: RG3280-DLP

IP-Dip-TPP (nanometer)

Alternative Designations: IP-Dip-TPP (nanometer)

GR hard resin-PuSL (micrometer)

Alternative Designations: GR hard resin-PuSL (micrometer)

Victrex AM™200 FIL-FDM

Alternative Designations: Victrex AM™200 FIL

PET-GF-FDM

Alternative Designations: PET-GF

PET-CF-FDM

Alternative Designations: PET-CF

HPPA-GF-FDM

Alternative Designations: HPPA-GF

PA6-FDM

Alternative Designations: PA6

PC FR-FDM

Alternative Designations: PC-FR

PC PBT-FDM

Alternative Designations: PC-PBT

PC ABS-FDM

Alternative Designations: PC-ABS

PPSU

Alternative Designations: PPSU

PA12-FDM

Alternative Designations: PA12

ABS-GF-FDM

Alternative Designations: ABS-GF

HPPA-CF-FDM

Alternative Designations: HPPA-CF

PA66 CF-FDM

Alternative Designations: PA66-CF

PEKK-FDM

Alternative Designations: PEKK

ULTEM1010-FDM

Alternative Designations: ULTEM1010

PEEK-FDM

Alternative Designations: PEEK-FDM

PA12 CF-FDM

Alternative Designations: PA12-CF

ASA-FDM

Alternative Designations: ASA-FDM

ULTEM 9085-FDM

Alternative Designations: ULTEM 9085-FDM

PLA-FDM

Alternative Designations: PLA-FDM

ABS-FDM

Alternative Designations: ABS-FDM

Nylon PA 12 Glass-Filled (SLS)

Alternative Designations: PA12GB

This is a whitish polyamide 12 powder that is glass filled. Its stiffness is excellent and it has good elongation at break.

Nylon PA 12 (SLS)

Alternative Designations: Polyamide 12

Nylon produces parts with long-term durability that is similar to that of standard plastic parts. Excellent stability for a long time.

PPS-FDM

Alternative Designations: Polyphenylene Sulphide

PPS has excellent strength of 80MPa and is highly rigid. It is resistant to high temperature, UV light, chemicals and creep.

PLA-FDM

Alternative Designations: Polyactic Acid

PLA is derived from renewable sources and is biodegradable. It can easily be melted and shaped without losing its mechanical properties.

PC

Alternative Designations: Polycarbonate

PC – Polycarbonate is a naturally transparent plastic with high strength and durability on impact. It is shatter resistant and heat resistant.

ABS

Alternative Designations: Acrylonitrile Butadiene Styrene

ABS (Acrylonitrile Butadiene Styrene) is a thermoplastic material widely known for its high resistance to impact and toughness.

PETG-FDM

Alternative Designations: PETG

PETG has significant chemical resistance, durability and good formability. It has low forming temperatures making it popular in consumer applications.

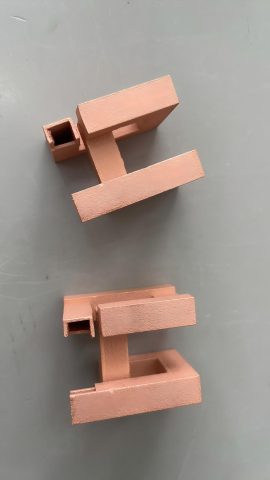

TC4-MBJ

Alternative Designations: TC4-MBJ

Nickel-based, titanium-based, iron-based, cobalt-based, heavy metal such as tungsten, precious metals such as gold, etc.-SLM (nanometer)

Alternative Designations: Nickel-based, titanium-based, iron-based, cobalt-based, heavy metal such as tungsten, precious metals such as gold, etc.-SLM (nanometer)

Pure copper-MBJ

Alternative Designations: Pure copper-MBJ

420-MBJ

Alternative Designations: 420-MBJ

3L6L-MBJ

Alternative Designations: 3L6L-MBJ

High-temperature alloys-SLM

Alternative Designations: High-temperature alloys-SLM

316L-FDM

Alternative Designations: 316L

17-4PH-MBJ

Alternative Designations: 17-4PH-MBJ

Mold steel 718-SLM

Alternative Designations: Mold steel 718-SLM

Aluminium 3.2315

Alternative Designations: EN-AW6082 | Al-Si1Mg

Typically formed by rolling and extrusion, Aluminium 3.2315 has medium strength with very good weldability and thermal conductivity.

Aluminium 3.3547

Alternative Designations: EN AW-5083 | Al-Mg4,5Mn

Aluminium 3.3547 / EN AW-5083 is a rolled plate with moderate strength. It is widely used in the capital goods industry.

Steel 1.0570

Alternative Designations: St52-3

Compared to other carbon steels, Steel 1.0570 has high electrical conductivity but low thermal conductivity and low ductility.

Steel 1.0038

Alternative Designations: EN 10025 | S235JR

Steel 1.0038 can be formed into many products. Its excellent weldability makes it to be widely used in bridges, transmission towers etc.

Stainless Steel 304 / 1.4301 / X5CrNi18.10

Alternative Designations: Stainless Steel 304 / 1.4301 / X5CrNi18.10

Stainless Steel 1.4301

Alternative Designations: X5CrNi18.10

Stainless steel 1.4301 is chromium-nickel austenitic stainless steel. The chromium element gives it excellent corrosion resistance.

PSU

Alternative Designations: Polysulfone

PSU (Polysulfone) is a transparent material. It is tough and rigid with good thermal stability and resistance to chemicals.

PPE - PS

Alternative Designations: Polyphenylene ether – Polystyrene

PPE - PS is a blend of polyphenylene ether and polystyrene. It is highly ductile and exhibits good resistance to impact.

PS

Alternative Designations: Polystyrene

PS (Polystyrene) is a transparent, amorphous thermoplastic. It is hard, brittle, rigid and resistant to gamma radiation.

PE

Alternative Designations: Polyethylene

PE (Polyethylene) has good strength ratio. It is resistant to chemicals, impermeable and exhibits good electrical insulation properties.

PET

Alternative Designations: Polyethylene terephthalate

PET has a melting point of about 270°C; hence, molding is done at a high temperature. It is a hard material with low moisture absorption.

PEI

Alternative Designations: Ultem

With a strong environmental resistance, PEI is highly stiff and stable. It is rigid and retains its strength at high temperatures.

PC - PBT

Alternative Designations: Polycarbonate-Polybutylene Terephthalate

PC - PBT has high toughness, dimensional stability and good resistance to heat and chemicals. It has good impact resistance and stiffness.

PBT

Alternative Designations: Polybutylene terephthalate

PBT has excellent resistance to abrasion and creep. It has a low coefficient of friction and a low moisture absorption.

Nylon PA 6/6

Alternative Designations: Polyamide 6/6 | Nylon 6/6

PA 6/6 is the most common variant of nylon used for engineering applications. It has a high melting temperature.

Nylon PA 6

Alternative Designations: Polyamide 6 | Nylon 6

The fibers are tough but retain high tensile strength and elasticity. PA 6 is extremely resistant to wear and good electrical insulation.

LDPE

Alternative Designations: Low Density Polyethylene

LDPE is the most flexible member of the polyethylene family. It offers good resistance to stress and pliability with good strength.

HDPE

Alternative Designations: High Density Polyethylene

HDPE is light in weight with high strength. It is resistant to chemicals and heat, impermeable and has good electrical insulation.

POM

Alternative Designations: Delrin, Acetal

POM is an easy resin for molding. It has a relatively high tensile strength as well as high resistance to wear, creep and warp.

Acrylic

Alternative Designations: PMMA

Acrylic (PMMA) is the most common form of clear, moldable thermoplastic, often used in place of glass due to its higher resistance.

PLA-FDM

Alternative Designations: Polyactic Acid

PLA is derived from renewable sources and is biodegradable. It can easily be melted and shaped without losing its mechanical properties.

PC

Alternative Designations: Polycarbonate

PC – Polycarbonate is a naturally transparent plastic with high strength and durability on impact. It is shatter resistant and heat resistant.

ABS

Alternative Designations: Acrylonitrile Butadiene Styrene

ABS (Acrylonitrile Butadiene Styrene) is a thermoplastic material widely known for its high resistance to impact and toughness.

TPV (rubber)

Alternative Designations: TPV (rubber) | Thermoplastic vulcanizate

TPE

Alternative Designations: Elastomer

TPE (Elastomer) exhibits excellent resistance to flexural fatigue. It has high impact strength and excellent chemical resistance.

PVC

Alternative Designations: Polyvinyl chloride

PVC (Polyvinyl chloride) is the third most synthesized thermoplastic material. It is resistant to weathering, chemicals, corrosion and shock.

Magnesium Alloy-AZ91

Alternative Designations: Magnesium Alloy-AZ91

Zamak 2

Alternative Designations: Zamak 2 | ZnAl4Cu3 | ZP0430 (EN) | AC43A (ASTM) | Z35541 (UNS)

Zamak 5

Alternative Designations: Zamak 5 | ZnAl4Cu1 | ZP0410 (EN) | AC41A (ASTM) | ZDC1 (JIS) | Z35531 (UNS)

The higher copper content gives Zamak 5 an improved strength but is less ductile than Zamak 3.

Zamak 3

Alternative Designations: Zamak 3 | ZnAl4 | ZP0400 (EN) | AG40A (ASTM) | ZDC2 (JIS) | Z33520 (UNS)

Zamak 3 is the most commonly used in the Zamak family. It blends its physical and mechanical properties excellently.

Aluminum Alloy-A356

Alternative Designations: Aluminum Alloy-A356

Aluminium ADC12

Alternative Designations: AlSi11Cu3

The ADC12 aluminium is more often used as an alternative for the A380 aluminium for parts that are highly intricate.

Aluminium A380

Alternative Designations: AlSi8Cu3

The A380 Aluminium gives an excellent combination of machinability, heat transfer and easy casting together with other properties.