Polyjet is a rigid photopolymer 3D printing technology that works by jetting UV curable resin onto a build tray in a process that is somewhat similar to inkjet printing. Polyjet 3D printing offers one of the most advanced industrial 3D printing solutions available, producing parts with incredible precision and speed. Polyjet is known for its speed and excellent surface finish. It is also capable of printing in multiple materials at once.

How does Polyjet technology work?

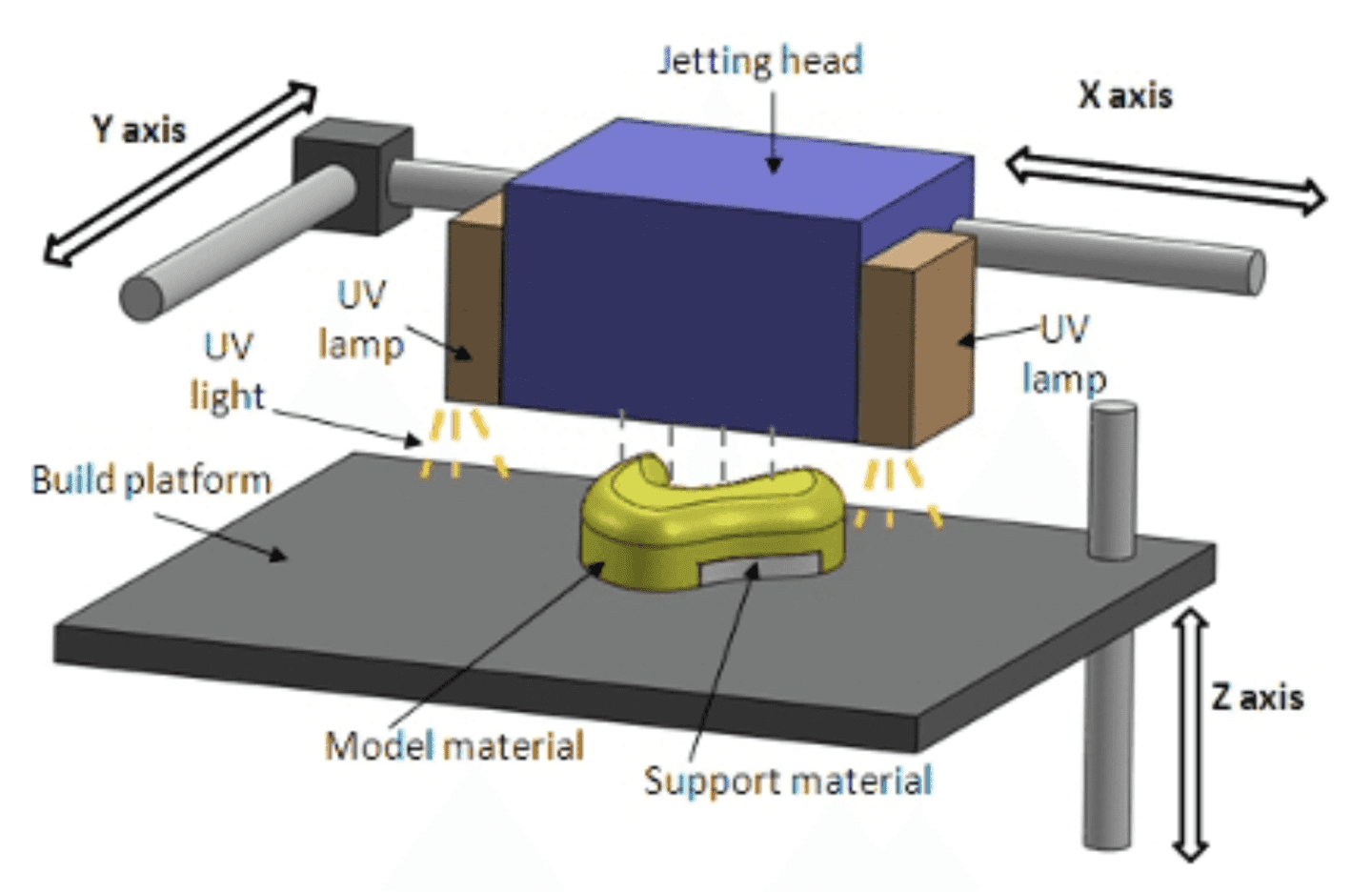

This process involves the liquid photopolymer material being cured layer by layer using UV light to manufacture a part. The process is similar to an inkjet printer.

The jetting head consists of multiple print heads which eject the photopolymer resin. These multiple print heads can store different materials or also materials with different colours. The Polyjet 3D printing process follows these main steps:

- Step 1 – The jetting heads deposit a single layer of the build material (typically photopolymers) by sliding to and fro along the X-axis and back and forth along the Y-axis according to the CAD data, onto the build platform. The depth of each layer is controlled selectively by the software.

- Step 2 – As soon as the droplets of these liquid photopolymers are jetted, they are immediately cured and hardened by the two UV lamps present on either side of the jetting head.

- Step 3 – When a layer of photo resin is cured, the build platform lowers in Z-direction to accommodate the next layer.

- Step 4 – The next layer of photopolymers is ejected from the print heads and the process is repeated till the object is complete.

- Step 5 – The part is finished by the removal of the support structures and if any further operations are required, they are performed during the post-processing.

As there are multiple print jets, different materials can be printed at once, like a batch. An instance of this functionality is a part requiring support structures, where the support material builds up at the same time as the main material which is not possible in other technologies where the support structures are built first and consumes time.

Materials for Polyjet 3D printing

Amongst the most frequently used materials for Polyjet, Xometry offers a Rigid Photopolymer in three colours (black, grey, white).

Advantages of Polyjet 3D printing

Polyjet is one of the most reliable, precise, and fast methods for prototyping, small batch production and also for industry-grade applications. It has a set of advantages that makes it unique.

Can print multi-material and multi-coloured parts

The main advantage of Polyjet is its ability to print multi-material and multi-colour parts. Since its multiple print heads can store different materials and different colours in its print jets, they can print multiple materials simultaneously, including the ability to blend different materials to create graded properties (e.g. a gradient from a Rigid Photopolymer to Rubber-Like Photopolymer for a part with progressively increasing flexibility). The process also allows for simulated overmolds for features like non-slip surfaces and rubber grips.

Easy and fast batch production

Another advantage of the multiple print jets is the ease of production of parts in bulk. It can build 20 objects at the same time as it would take for one single object with its counterparts like FDM or SLA.

Smooth Surface Finish

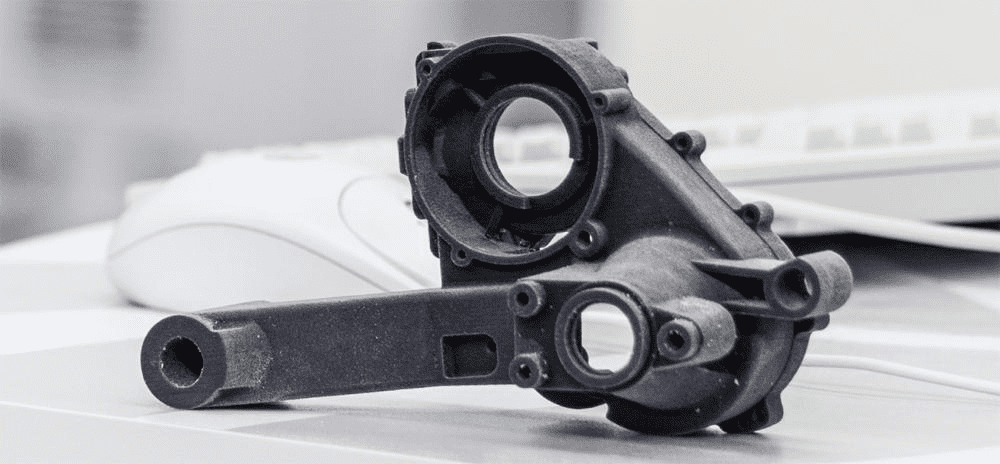

Unlike many other 3D printing processes like FDM or SLS, PolyJet produces parts with a smooth surface finish resembling the look and feel of a final product. This is due to the combination of PolyJet’s thin layer height and the resin quality itself. Excellent choice for tangible objects like Joysticks, camera accessories, etc.

Excellent dimensional accuracy and resolution

The dimensional accuracy obtained through Polyjet is up to 0.1-0.3mm and the layer resolution is up to 16 microns which makes it one of the top technologies in terms of accuracy and resolution. It is a good choice for prototypes to show a feature accurately in high definition to give a good overview.

Good for complex designs

Even though Polyjet utilizes support structures, it is good for complex designs since it uses resins unlike its counterparts like SLS and MJF which uses powders. The resin usage gives fluidity to the design which helps in achieving the complex designs and complex internal features.

Less material wastage

Since the Polyjet printer prints by deposition of the photopolymer resin and solidifying it, there is no chance of wastage involved like in MJF or SLS where the powder is used and prone to wastage. There is also a chance of eliminating the support structures when the model is designed carefully.

Disadvantages of Polyjet 3D printing

Apart from the advantages it offers, there are also a few common disadvantages that polyjet possesses.

Expensive technology

Polyjet is expensive compared to its cheaper counterparts like MJF and FDM that also are widely used to build prototypes.

Use of support structures

The use of support structures is not a hindrance in terms of design complexity but the removal of support structures can create marks on the surface. Support material also creates alterations in surface quality. For example, no support gives a glossy, smooth finish whereas with support the surface appears dull and a little rougher.

Limited materials to print

Polyjet printing does not offer a wide selection of materials to print like FDM. Even with resins, it only utilises photo resins which makes the technology very limited with build materials.

Xometry’s Polyjet 3D printing services

Xometry Europe offers Polyjet 3D printing services online, for on-demand 3D printing projects, for both prototypes and large batches. With a network of more than 10,000 partners worldwide, Xometry is able to deliver polyjet 3D printing parts in up to 7 days. Upload your CAD files to Xometry Instant Quoting Engine to get an instant quote with various manufacturing options available for polyjet 3D printing.