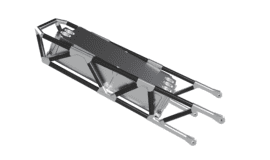

Asat Launches A High-Power Rocket With Parts Manufactured By Xometry

Industry: Aerospace Manufacturing processes used: CNC machining Challenge: To manufacture a high-power rocket with components able...

Read moreManufacturing on Demand for Engineering Students & Schools

At Xometry, we genuinely appreciate the pioneering spirit of inventors, educators, students, and explorers. These are the people building the future of the industry and we want to support them in their effort to make scientific and technological progress.

Xometry provides streamlined access to manufacturing technologies, allowing students to explore, experiment, and bring their ideas to life using techniques ranging from precision CNC machining to rapid 3D printing.

Our global network of over 10,000 carefully vetted manufacturing partners helps to quickly get quotes and source custom parts on demand to innovate and test projects. The platform also provides Design for Manufacturability (DFM) feedback, which makes getting parts an effortless process.

Industry: Aerospace Manufacturing processes used: CNC machining Challenge: To manufacture a high-power rocket with components able...

Read more

Recently, Xometry supported the student Formula team from the University of Naples Federico II, the oldest public university in the world, by producing...

Read more

The case study is prepared in collaboration with the Press, Partnership and Sponsorship team at Warwick Moto. With the electrification of motorsport...

Read more

It all started in June 2020 when Elon Musk’s Boring Company announced the first-ever “Not-a-Boring Competition”, which aims to create innovative...

Read more

Industry: Transportation Manufacturing processes used: Sheet Metal Challenges: Developing a fully operational Hyperloop prototype...

Read moreXometry offers more than 15 manufacturing processes on a single platform, including CNC machining, sheet metal fabrication, and 3D printing services. For high-volume parts production, we also offer injection moulding and die casting services. In addition, the platform has a wide selection of metals (aluminium, steel, and stainless steel alloys) and plastics (ABS, POM/Delrin, etc.). And of course, we always find the right provider with free capacity thanks to a network of 10,000 highly-qualified suppliers globally.

Simply upload your CAD file, select your manufacturing options, get an instant quote, and order in just a few clicks. You can import multiple designs at once in a single quote and choose the required specifications for each part. Xometry handles the project management, logistics, and shipping, which helps you shorten project times.

Design for Manufacturing (DFM) is crucial for students in prototyping projects as it ensures that the designed product can be produced in an efficient and cost-effective way using processes like CNC machining, sheet metal fabrication, and 3D printing. This is why Xometry helps students optimise their CAD file and ensure the manufacturability of their parts.

Choose from thousands of possible combinations of materials, surface finishes, tolerances, and certifications. Xometry offers over 15 manufacturing technologies, over 130 materials (metals and plastics), and custom alternatives to provide a bespoke production experience. Our network can also produce parts with tight tolerances.

Xometry offers a large selection of post-processing options (anodising, polishing, electroplating, powder coating, heat treatment, etc.) as well as custom alternatives. These finishes can improve the aesthetics and mechanical properties, such as biocompatibility, water-resistance, strength, etc.

At Xometry, we know that creating a proper prototype takes time and money. That’s why we designed our Instant Quoting Engine to help you find the best technical alternatives for your project in just a few clicks. You instantly see the price difference based on your chosen settings. Need some advice? Our sales team and sales engineers can help you throughout the entire manufacturing process—including the design phase.

The seamless integration of our Manufacturing Partner Network, the in-house Applications Engineering Team, and the Xometry Quality Assurance Lab enable us to ship every part with confidence under the Xometry Quality Control.

All uploads are secure and confidential.