It all started in June 2020 when Elon Musk’s Boring Company announced the first-ever “Not-a-Boring Competition”, which aims to create innovative solutions for boring tunnels. The challenge involved quickly and accurately drilling a tunnel that was 30 m long and 50 cm wide. About 400 teams applied to enter the competition but only 12 of them were shortlisted to go to Las Vegas and give a demonstration of their technology.

After being selected to take part, the TUM team founded the nonprofit organization “TUM Boring” and quickly grew to a team of around 60 students from 16 different countries and universities. The thing that unites them all is their dedication to the future of mobility: they believe that traditional tunnelling technology will be replaced by more modern solutions and want to shape the future of tunnelling together through innovative concepts.

Designing a complex boring machine with both standard and innovative concepts

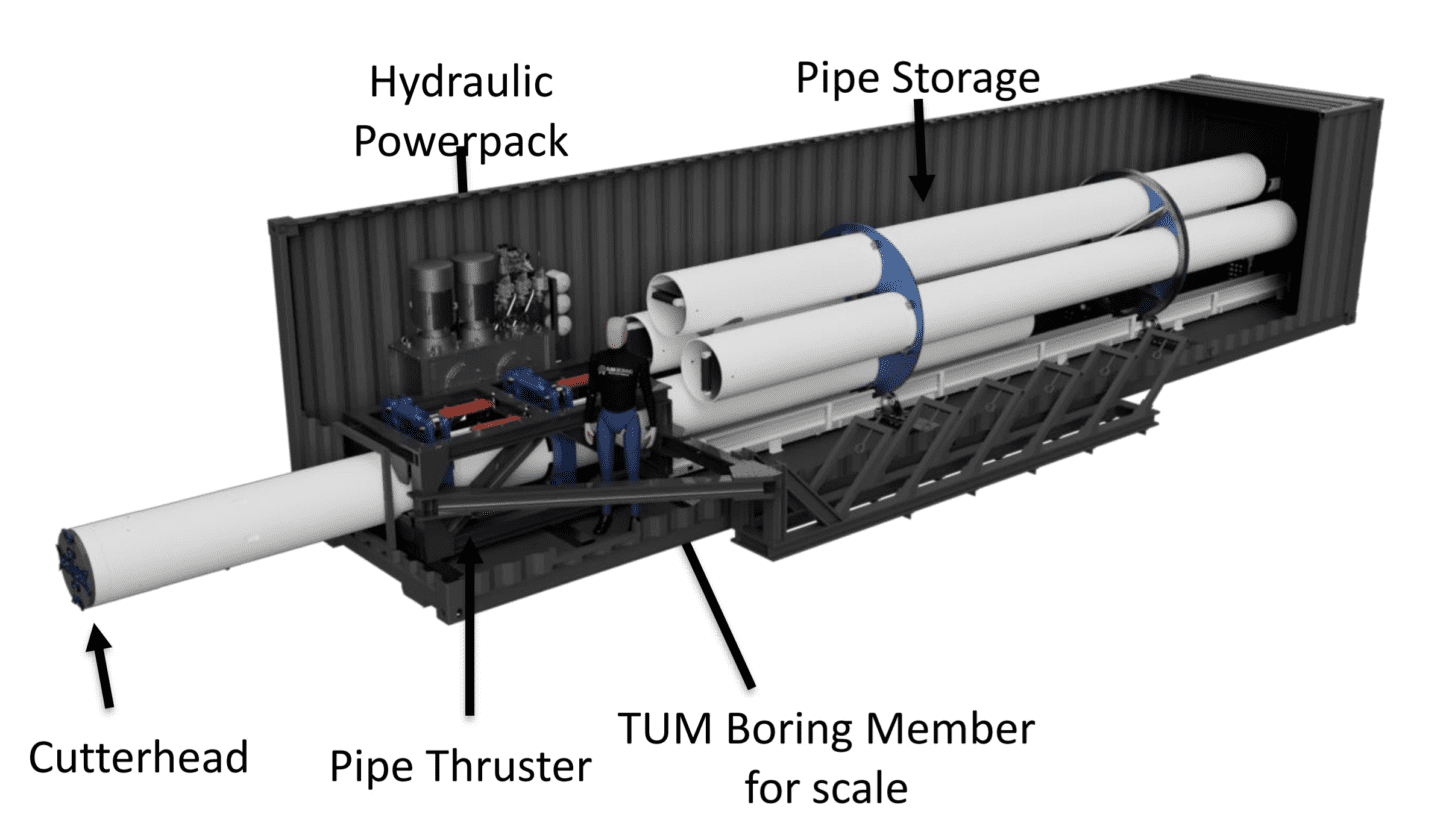

The TUM Boring team had been working on their design for over a year to produce the final structure they showcased in Las Vegas. Their 22-tonne tunnel boring machine (TBM) is a complex assembly that uses a mix of conventional industrial methods like pipejacking and innovative approaches such as revolver pipe storage that reduces downtime between pipe segments.

The whole structure relies on many different subsystems that have to work seamlessly and simultaneously:

- The cutterhead digs a tunnel with a diameter of approximately 0.5 m by loosening and excavating the soil.

- The material removal system, which takes the dirt out of the tunnel, consists of 6 conveyor belts integrated into the pipes and an auger conveyor which removes all material from the drilling process. This dry excavation method combined with the use of conveyor belts paves the way for a higher material removal rate, thus increasing the boring speed.

- The hydraulically actuated propulsion system is located in the start pit and supports jacking forces up to 500 kN to push the tunnel segments with the cutterhead at the front. By using two alternating hydraulic cylinder arrangements, it provides a continuous forward motion, which is revolutionary in the tunnelling industry.

- The revolver pipe storage at the back contains all of the tunnel segments and allows you to quickly switch to the next segment with minimal downtime with the help of a motor-driven gear system.

Additional systems are responsible for steering, guidance, control and power management.

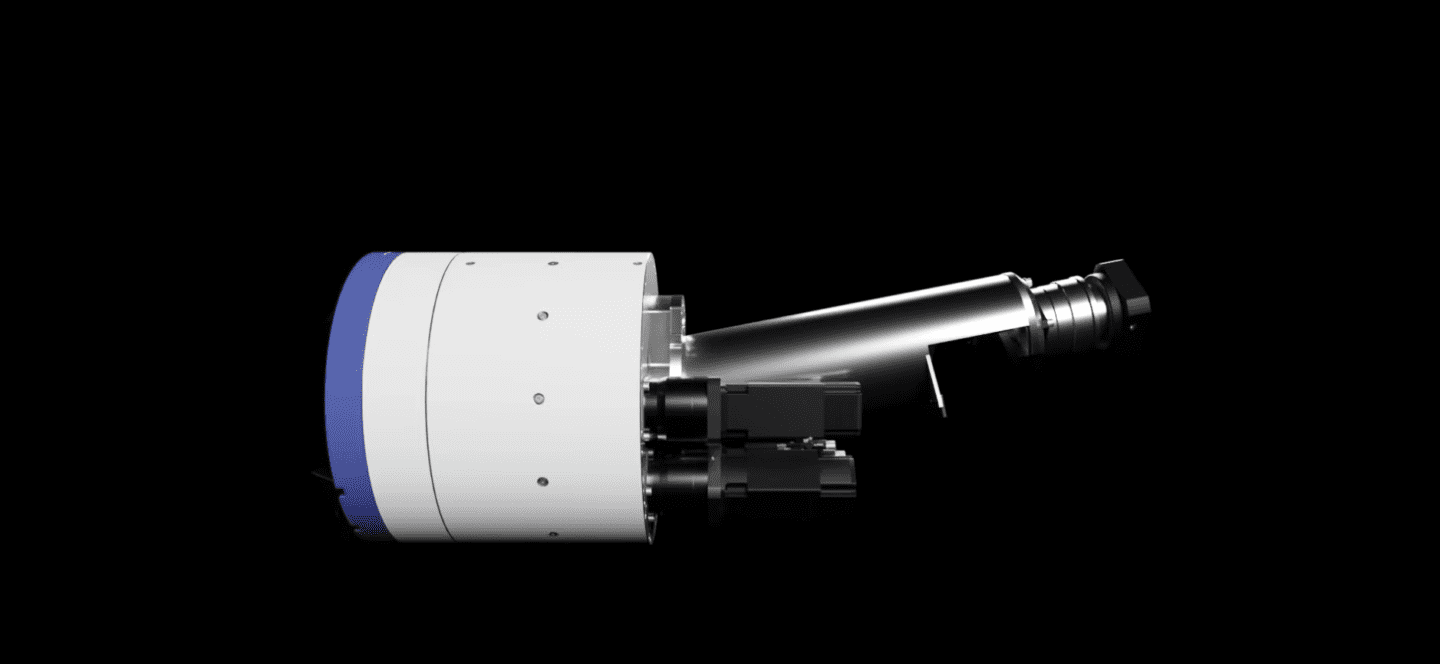

The cutterhead: the masterpiece of this TBM

Out of all of the tunnel boring machine components, the most extraordinary one was undoubtedly the cutterhead. It consists of multiple parts: a cutting wheel, a rotating drum, a housing, a sealed bearing, a mechanical face sealing, a ring gear, four synchronous motors and an auger with suitable housing and bearing.

Building the cutterhead was one of the biggest challenges of the project as the structure had to combine all of these different components while being extremely robust and powerful enough to remove the soil in front of it.

Sourcing custom parts with Xometry on very short notice

Almost every mechanical component, such as the massive CNC machined steel parts for the cutterhead, the conveyor belts, the pipe storage and the propulsion mechanisms were custom-made to fit the team’s needs.

Xometry provided the team with various essential and complex CNC machined steel parts for the steering joint of the tunnel boring machine, laser-cut sheet metal parts for the mechanics of the propulsion system, as well as the foundation of the eight-ton capacity heavy pipe storage system.

“The project had a very ambitious timeline since we had to plan, produce, test and ship our complex machine all within one year. The short and scheduled delivery times from Xometry were a great help in achieving this,” shares Dmitry Burlakov from the TUM Boring team. “We were also really satisfied with the quality of the parts provided by Xometry”.

Winning the Not-a-Boring Competition in 2021

There were several success factors that helped make winning the competition possible. “The most important factor was the team with so many highly motivated students who worked day and night to achieve the ambitious goals,” explains Dmitry. “However, our valued industry partners like Xometry that provided us with resources and knowledge contributed to our success. This support allowed us to be well prepared for the competition, which ultimately gave our team the edge.”

The TUM Boring team was one of the final two competitors remaining after the safety briefing, which was conducted four days before the competition and ruled out the other ten participants. TUM Boring managed to meet the required safety standards to tunnel for the entire stretch and to drill up to 22m—the longest distance recorded during the Not-a-Boring Competition.

The team is now planning their next steps with the same goal of building the world’s fastest tunnel boring machine and contributing to the future of mobility.

About Xometry

Xometry is the world's leading on-demand manufacturing platform. We offer massive network capacity, instant online quotes, and reasonable pricing. Our worldwide network of over 10,000 manufacturing workshops enables us to consistently maintain fast lead times while offering a wide range of capabilities, including CNC Machining, 3D Printing, Sheet Metal Fabrication, and Injection Moulding. Xometry works with a diverse customer base, ranging from startups to Fortune 100 companies such as BMW and Bosch.