Tolerances play a key role in the final dimensions of the part in any manufacturing process and additive manufacturing is no exception. Hence, it is essential to understand the tolerances in 3D printing for prototyping as well as for functional parts for maximum accuracy.

What are the tolerances in 3D printing?

Tolerances generally mean the deviation in the dimensions from technical drawing or CAD model to the tangible part that is manufactured. Tolerance is the amount of random deviation or variation permitted for a given dimension. As of November 2021, there are no international standards on tolerances for 3D printing like for CNC machining.

In 3D printing, the major factors influencing the tolerances are:

- Material shrinkage (change in volume from a change in state from liquid to solid)

- Layer thickness

- Minimum feature size

- Build size (maximum size of the part to be printed, depending on the technology)

Material shrinkage

The build material used in the 3D printing processes includes thermoplastics filaments, powders, resins, liquid photopolymers and metal powder. All these materials have a varying degree of shrinkage. As a principle of 3D printing, the polymers naturally shrink when they are cooled and solidified during the printing process. The rate of shrinkage is specific to a definite material.

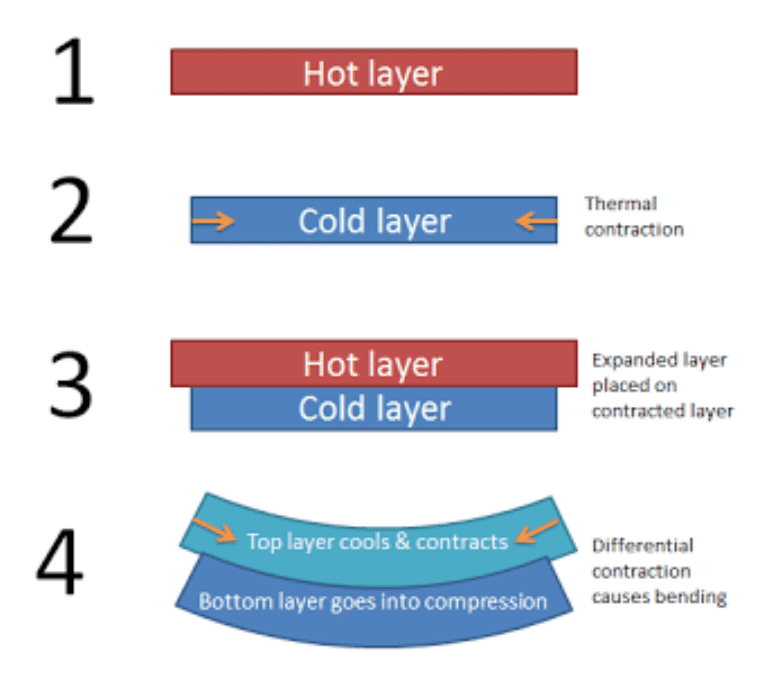

On top of it, uneven shrinkage leads to defects like warpage that alters the part geometry and happens with rapid changes in temperatures. Different materials act differently to the printer settings, uneven cooling and add to inaccuracy in the geometry. Stresses during build, support strategy and other geometry considerations may cause deviation in both tolerances and flatness.

Parts with thicker geometries, flat or broad parts, and parts with uneven wall thicknesses, may be prone to significant deviations or warp. Low quality plastics and uncalibrated printer settings account for inaccurate dimensions.

Layer thickness

Also known as resolution, layer thickness impacts the dimensional accuracy of the part in Z-direction. Its impact is mostly seen in FDM, Polyjet and SLA where the part adheres to the bed. This arises when the base or bottom of a part is next to the bed.

Heating and curing cause warping and often the initial base layer of a print is programmed with extrusion rates of more than 100% to ensure that the part sticks to the bed. This results in a thicker initial layer and the resulting dimensions greater than desired.

Also, cheap and desktop printers are highly inconsistent with their layer heights and hence cannot stick to tight dimensions. Whereas, for technologies like SLS, DMLS, the default resolution is already adequate for most applications or the layer height is already pre-set by the machine manufacturer. Whereas, good build material is required as the cheap materials are often unpredictable with their behavioural properties like shrinkage etc.

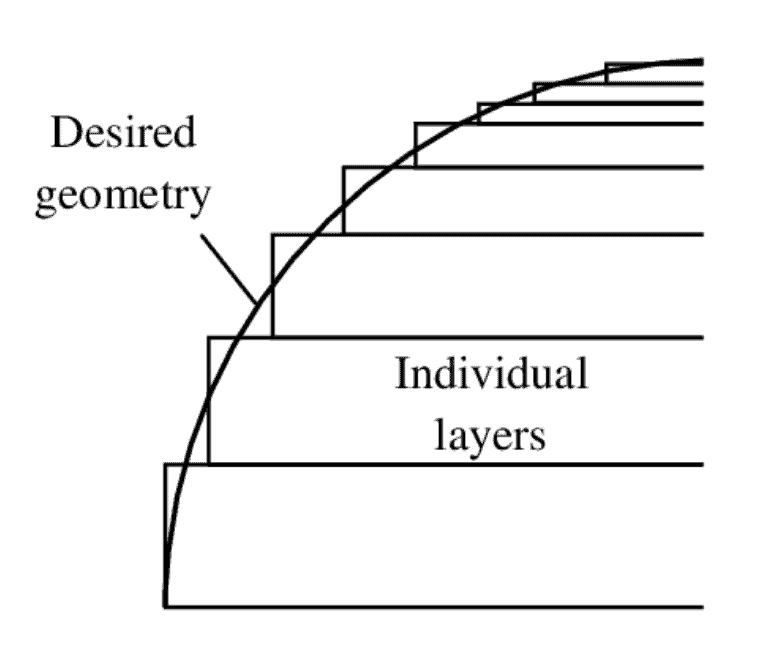

One more important thing is the layer stair-stepping effect. Since a 3D printer prints the parts in layers, spheres or circles cannot be as smooth or accurate as done with conventional machining, rather they are as shown in the picture below. This clearly doesn't abide by accurate dimensions but is a little deviation from those.

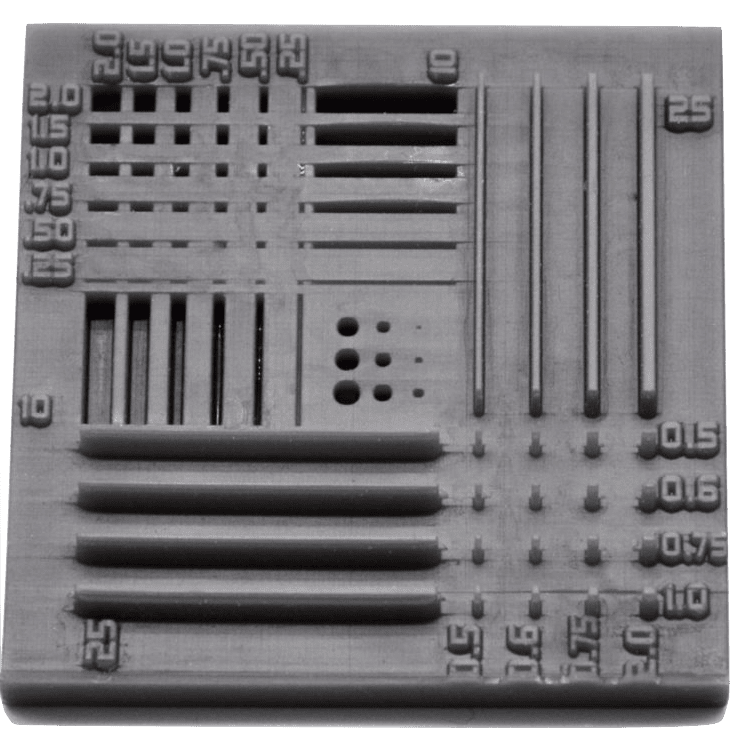

Minimum feature size

For FDM, the minimum feature size is the function of nozzle diameter and layer thickness. The minimum feature size in X-Y is determined by the nozzle diameter. The feature height in the Z direction is determined by the layer thickness. The nozzle diameter affects the overall level of detail almost exclusively in the horizontal plane (parallel to the print surface).

For example, a smaller nozzle will be able to print a more detailed text – assuming it’s placed on the top side of the printed object. Contrary to that, the layer height affects the level of detail on the vertical and slanted sides of an object.

In other technologies like MJF, SLS, DMLS and SLA, the minimum feature size is a function of the build material and also the laser beam diameter. In power based technologies, the material is reused. On multiple usages, the powder becomes less spherical and loses its shape. Hence it’s unpredictable how much the new, irregular shape affects the dimensions.

The point to be noted is that the nozzle diameter and laser beam diameter are constant (customization available) and as mentioned above about the layer thickness, it also is prone to inaccurate dimensional adherence which makes the minimum feature size also a factor that affects the tolerances.

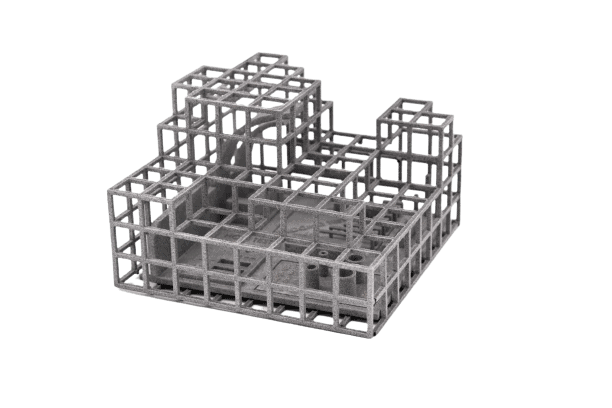

Build size

Build size refers to the maximum overall size of the part that can be manufactured by a printer or the maximum size that is fitted onto a build area in a printer. The bigger the part, the more time required for it to cure or cool down. During this process, a lot of shrinkage and warpage takes place due to uneven cooling.

Big parts also require a lot of support structures (depends on design and process though). When removed, it also affects the surface quality.

Tolerances in 3D printing technologies

Various technological processes of 3D printing have varied tolerances that are specific to the process. They are due to the mechanism of the technology, moving parts, the material used and factors like the design of the part. For a better print, it is recommended to follow the design guidelines specific to the process.

HP Multi Jet Fusion Tolerances

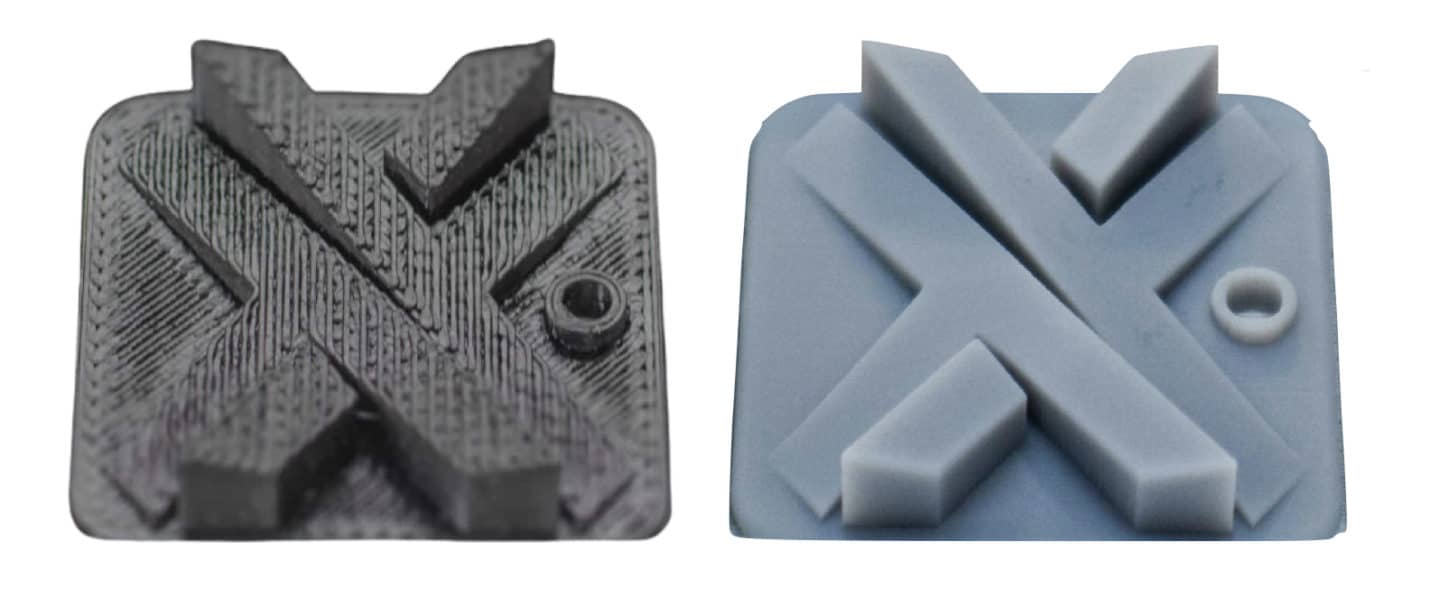

In Multi Jet Fusion, heat is produced due to UV laser and which leads to the thicker geometries, large broad parts, and parts with uneven wall thicknesses to deviate due to thermal shrinkage and stress. This can look like warping or twisting. The wall thicknesses and design guidelines as injection moulded parts can be used while designing for MJF.

| Parameter | Value |

| Tolerance | ±0.3% (± 0.2 mm for 100mm) |

| Build volume | up to 380 x 284 x 380 mm, while we normally recommend the maximum size of 356 x 280 x 356 mm |

| Layer thickness | ~0.08 mm |

| Minimum feature size | min 0.5 mm, 0.7 is recommended |

Read MJF 3D printing design guidelines.

Selective laser sintering (SLS)

Selective laser sintering is almost similar to the MJF process wherein, this process employs Co2 laser as a source of heating the polymer powder. Shrinkage and warpages are common to both SLS and MJF.

| Parameter | Value |

| Tolerance | ±0.3% (± 0.3 mm for 100mm) |

| Build volume | up to 340 x 340 x 605 mm, but usually, we recommend the maximum size of 320 x 320 x 580 mm |

| Layer thickness | ~0.1 mm and for water-tight parts 1.5 mm, when the wall thickness is higher |

| Minimum feature size | min 0.5 mm, 0.75 is recommended |

Read SLS 3D printing design guidelines.

Stereolithography (SLA)

SLA technology offers high detail and accuracy with a variety of photopolymers that can mimic different properties. SLA materials can range from flexible (polypropylene-like), general-purpose (ABS-like), rigid (polycarbonate-like), and even highly stiff composite depending on the chosen material. However, parts need to be cured under UV light to harden for some time and it leads to shrinkage.

| Parameter | Value |

| Tolerance | ±0.2% (± 0.2 mm for 100mm) |

| Build volume | up to 736 x 635 x 533 mm |

| Layer thickness | ~ 0.02 |

| Minimum feature size | 0.1mm |

Read SLA 3D printing design guidelines.

Fused deposition modeling (FDM)

Fused deposition modeling works well for mechanical geometries, larger parts, and parts that may not require ultra-fine features. Very narrow features may not resolve due to the extruded material width deposited through the nozzle. Shrinkage takes place immediately as the material starts cooling as soon as it is laid on the build platform. There is also a variation in tolerances between industrial and desktop FDM printers.

| Parameter | Value |

| Tolerance | ±0.3% (± 0.3 mm for 100mm) |

| Build volume | up to 914 x 610 x 914 mm |

| Layer thickness | ~0.05-0.3 mm |

| Minimum feature size | up to 0.2mm |

Read FDM 3D printing design guidelines.

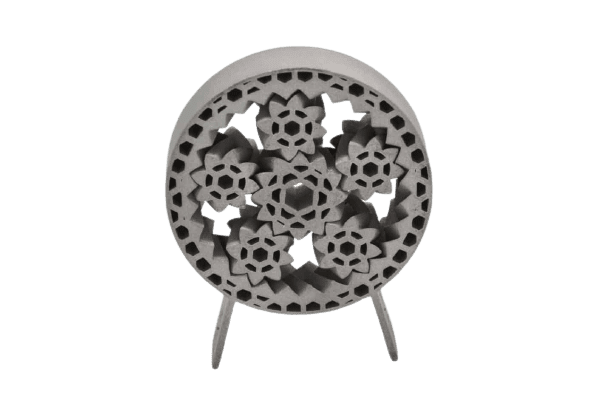

Carbon DLS

Carbon DLS is a detailed and accurate process with thermally cured engineering materials. The cured materials are often urethane-based, such as flexible, rigid, and elastomer materials (FPU, RPU, EPU).

There are also materials that behave like silicone, such as the urethane-based SIL material. Cyanate ester (CE) is a stiff and highly thermal resistant material. Urethane Methacrylate (UMA) is a general-purpose single-stage resin. However, the resin needs curing to set in and this leads to shrinkage.

| Parameter | Value |

| Tolerance | ±0.1% (± 0.1 mm for 100mm) |

| Build volume | up to 119 x 189 x 300 mm. Recommended size: Within 100 x 100 x 150 mm |

| Layer thickness | ~0.1 mm |

| Minimum feature size | min 1 mm is recommended |

Read Carbon DLS 3D printing design guidelines.

Direct metal laser sintering (DMLS)

The DMLS process involves a lot of heat and results in shrinkage and warpage. The rate of shrinkage and heat conductive properties of metals is different from plastics. The parts are almost pore-free, with less surface roughness (~20 µm).

| Parameter | Value |

| Tolerance | ±0.2% (±0.1 – 0.2 mm for 100mm) |

| Build volume | 250 x 250 x 325 mm |

| Layer thickness | 0.02 – 0.08 mm depending on the material |

| Minimum feature size | 0.75 mm for cosmetic features, 1.5 mm for structural features |

Read DMLS 3D printing design guidelines.

Post-processing

Most technologies produce support structures. Removal of the supports not only affects the surface finish but also sometimes leads to material removal at that point. This creates inaccuracy in the dimensions.

Finishing processes like sanding can be used to cut out extra dimensions whereas techniques like coating and painting can add little to the dimensions. In DMLS, sometimes 1–2 mm of additional material is applied to significant surfaces and is machined accordingly after printing. This is a way to correct the dimensions and achieve tight tolerances.

Conclusion

The table below summarizes the tolerances of Xometry’s 3D printing processes:

| 3D Printing Technology | Tolerances |

| MJF | ±0.3% (± 0.2 mm) |

| SLS | ±0.3% (± 0.3 mm) |

| SLA | ±0.2% (± 0.2 mm) |

| FDM | ±0.3% (± 0.3 mm) |

| Carbon DLS | ±0.1% (± 0.1 mm) |

| DMLS | ±0.2% (±0.1 – 0.2 mm) |

| Polyjet | ±0.05-0.1mm |

Xometry Asia offers fast, reliable, and highly accurate 3D printing services. Through our Instant Quoting Engine and our network of over 10,000 manufactures, we ensure that you experience a seamless part production process, from quoting to doorstep delivery.