Stereolithography is a 3D printing technology that creates parts through a process known as photopolymerisation. In this process, ultraviolet light is focused in a vat of resin. The ultraviolet light beams in the shape of the object to be produced solidifying it layer by layer. After each layer is produced, it is raised out of the vat and the process is repeated.

Size limitations

The maximum build size offer by Xometry for SLA is 480 x 480 x 560 mm, while the minimum printable feature size is 0.1 mm. Achievable tolerance is ±0.2% (min. 0.2 mm).

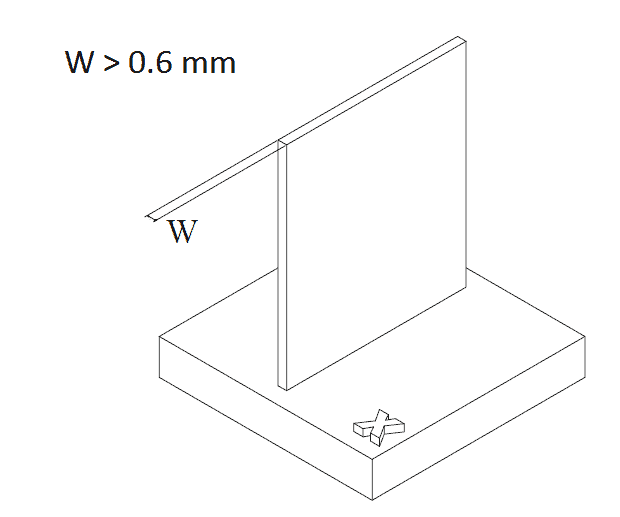

Wall Thickness

The recommended minimum wall thickness for unsupported walls is 0.6 mm. Walls that are supported on both sides can be designed with a minimum thickness of 0.4 mm as these are less likely to warp.

Overhangs

SLA printing utilizes a lot of support structures. Usually, slicing tools detect necessary positions for support structures in a model and add them. Hence, overhangs are usually no problem. However, if it is necessary to print without support, unsupported overhangs must not be more than 1 mm in length and be at a minimum angle of 19°.

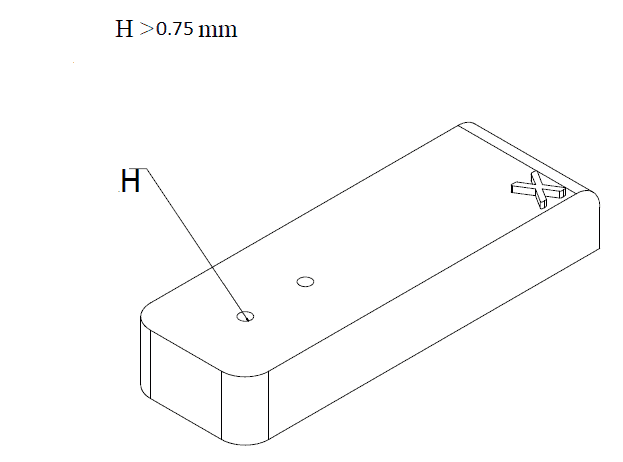

Holes

To ensure that holes do not seal off during printing, design them with a minimum diameter of 0.75 mm. For holes longer than 12 mm. The minimum diameter can be slightly increased.

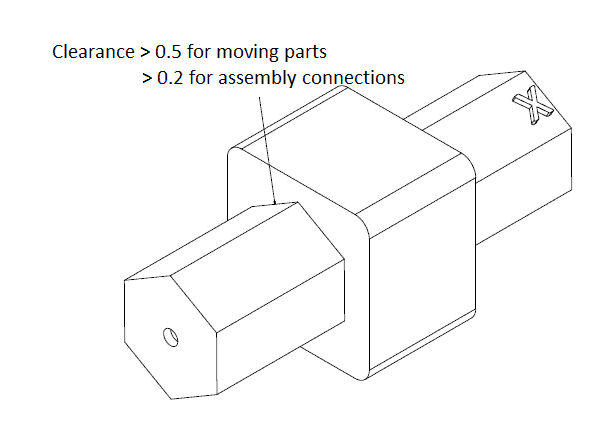

Assemblies

SLA can print fully functional assemblies. However, adequate clearances must be designed between mating parts to prevent the assembly from turning into a single solid unit. Minimum clearances of 0.5 mm between moving parts and 0.2 mm for assembly connections are recommended.

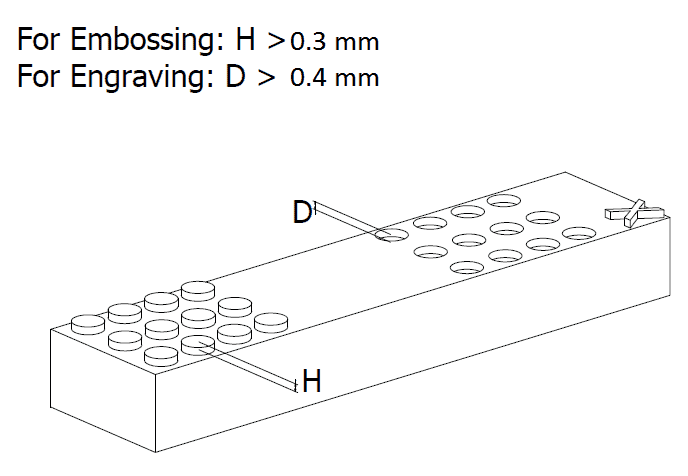

Engravings & Embossing

The precision of SLA makes it suitable for printing embossed and engraved details including texts. Embossed features must be at least 0.3 mm in height and 0.4 mm wide, while engraved features require a minimum depth of 0.4 mm and a width of 0.5mm.

Do you want to have your designs 3D printed? Simply upload them to the Xometry Instant Quoting Engine℠, and get design-for-manufacturability feedback as well as a quote with price and lead time options in seconds!