Dr. Deidre Quinn-Gorham remembers the lightbulb moment when she began thinking about how to introduce 3D printing into her profession. “I had heard about 3D printing off and on but a couple of years ago my step dad gave me a magazine issue of National Geographic and showed me this article that was entitled ‘Just Press Print,’’ she recalled in an interview. “And it had this beautiful layout of some of the things that you can utilize 3D printing for, and it spanned from printing of food to clothing material to actual organs.” Shortly afterward, she read an article in a veterinary medical journal about someone who 3D printed a skeletal model of a dog.

As the coordinator of educational programs and instructional technology at Tuskegee University’s College of Veterinary Medicine, this was just the kind of technological use case Quinn-Gorham was keeping an eye out for. What does that title mean? “My job is to develop educational programs to incorporate into the curriculum and scope out innovations in technology that would enhance teaching and learning,” she said. “If I find a particular technological tool that I think would enhance the teaching process or the students’ learning, then I will investigate that particular item and present that to the dean, and we go from there to see if it is feasible for our instructors and students.”

3D printed pet bones

She also has a Doctor of Veterinary Medicine degree. “I really got hooked onto technology when I was in veterinary school and we were required to take computer classes in which they introduced various software programs to us, and it just kind of escalated from there,” said Quinn-Gorham. “I never lost that desire to learn more about the technological advances that were out there and combine that with veterinary medicine.”

This background helped as Quinn-Gorham began thinking about how she could leverage 3D printing in the veterinary school’s curriculum. She started by visiting the department of aerospace science engineering at her school, which had recently utilized 3D printing to build a small-scale model of a solar-powered house. She was soon introduced to Dr. M. Javed Khan, the department head of aerospace science engineering. “I told him that I wanted to see their 3D printing in action because I have some ideas for how it could be used in veterinary medicine,” she recalled. “So he invited me over and that’s when the journey began to unfold.”

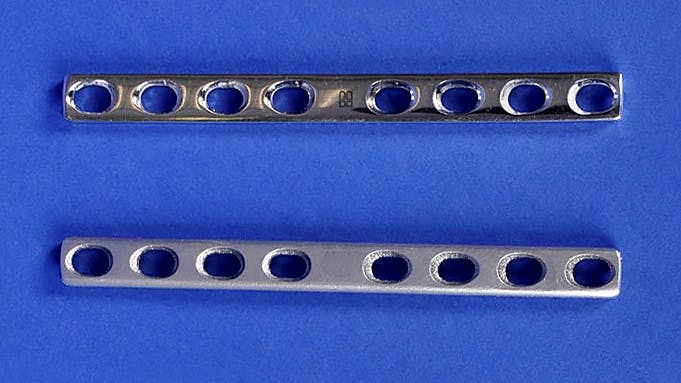

Quinn-Gorham started the project by going to a former surgical instructor of hers, Dr. Howard King, and asking him for a metal plate that’s often used to repair fractures in dogs. Her thinking was that veterinarians could use 3D printing and modeling to reproduce metal plates and possibly other surgical instruments. In another scenario, her former instructor also mentioned how veterinarians could 3D print a version of the fractured bone so that they can evaluate the fracture before the surgical procedure and show it to the pet’s owner to better explain the nature of the injury.

3D printed plates that can be used to repair fractures in dogs

When Quinn-Gorham returned to her university’s engineering department, they were able to use a 3D printer to print a smaller version of the metal plate in plastic. To get an idea of how the plate would look in its metal form, she started looking around for other solutions, and that’s wen she discovered Xometry. After getting a high-resolution scan of the plate and having it converted into a CAD file, she sent it over. “Xometry gave me back some excellent models,” she said. “The plate was actually printed in aluminum because the stainless steel was a little costly and I had a limited budget.”

So does this mean the veterinary school will immediately begin incorporating 3D printing into its curriculum? Well, not quite yet, but Quinn-Gorham’s experiment got the ball rolling. “One thing that came as a result of my interacting with the school of engineering is that we’ve formed a partnership,” she explained. Recently, the department of aerospace science engineering acquired a brand new 3D printer. “Over the summer, I acquired a scapula — which is a shoulder bone of a dog — that I brought over. They scanned it for me and printed out a couple of samples in different sizes.”

Why is this significant? Well, veterinary schools often have a difficult time obtaining an adequate number of animal bones — which come in many different shapes and sizes depending on the breed — to use in their teaching. “The 3D printed versions last longer than actual bones and are a little more resistant to breakage,” said Quinn-Gorham. “If you drop a bone and it’s an older specimen, you might chip off a structure that’s a landmark for that particular part of the anatomy and you can no longer use it. These lightweight materials give a little more resistance to breaking. Besides, if a 3D-printed specimen breaks, you can just print out another one.”

But that’s only the beginning. Quinn-Gorham is already thinking ahead to other uses the school can get from the technology. “Anytime you have a chance for interdisciplinary collaboration, it opens the door to so many possibilities for new ventures in education and funding opportunities for both areas,” she said. “So it is a win-win situation every way you look at it.”