Corrosion is defined as the natural process that causes the transformation of metals into undesirable substances when they react with corrosive mediums like water or air.

Corrosive mediums convert the metal into their respective oxides, sulfides and hydroxides (e.g rusting in iron) which cause damage and disintegration of the metal starting from the portion of the metal exposed to the environment and spreading to the complete metal.

Corrosion resistant metal parts, on the other hand, offer resistance to these reactions and can hence be used in many fields from culinary to defence. To create such parts, two solutions stand out: choose corrosion resistant metal materials that are usually processed by CNC machining, Sheet metal fabrications and 3D printed via direct metal laser sintering (DMLS), or improve the parts’ resistance thanks to post-processing options.

Way 1: Choose from the selections of common corrosion resistant metal materials

Stainless Steel

Stainless steel is a family of about 200 alloys of steel with high heat and corrosion resistance. The carbon percentage ranges from 0.03% to 1.2% while its unique characteristic is the high amount of chromium. Stainless steel consists of about 10.5% of chromium that creates a passive oxidation layer that protects the metal from corrosion.

Stainless steel can be classified into 3 main categories based on its microstructure:

- Austenitic Stainless Steel: Austenitic stainless steel consists of at least 18% of chromium and 8-12% nickel. It also has a mix of nitrogen, carbon, and many other elements. Chromium imparts high corrosion resistance, while nitrogen acts as a stiffening agent. This range of alloys is called 300-series stainless steels and common grades include stainless steel 304 and stainless steel 316 while the latter being the most corrosion-resistant material.

- Martensitic Stainless Steel: Martensitic stainless steels usually contain 11.5–13% of chromium, 0.15% carbon, 0.1% manganese, molybdenum and sulphur or selenium. The range is called 400-series with the common grade being 420A. Carbon imparts strength to the alloy while the low chromium content makes it less corrosion resistant compared to the 300 series.

- Ferritic Stainless Steel: Ferritic stainless steel is termed as a straight chromium non-hardenable class of stainless alloys that consist of chromium ranging from 10.5% to 30% and a carbon level below 20%. These steels cannot be hardened by heat treatment but can be slightly hardened by cold rolling. These are also a part of the 400-series while the 430A is the typical grade.

Duplex Stainless Steel

Duplex steel alloy contains two different phases as the name suggests. Duplex steels take the best properties from ferritic and austenitic phases and combine them into the most advanced corrosion-resistant metal. Typical grades are S32750 with 25% chromium, 7% nickel, and 4% molybdenum and 2205 with 22% chromium, 5% nickel, and 3% molybdenum. They are used in various challenging operations.

Superalloys

Superalloys are high-performance metal alloys that offer corrosion resistance at high temperatures and excellent mechanical properties and. This is why these grades of corrosion-resistant metals are often used where high performance and corrosion resistance is needed (like aerospace and medical).

Superalloys are differentiated by the main matrix element:

- Nickel Superalloy: Nickel-based superalloys not only offer excellent corrosion resistance but offer high strength and thermal resistance due to their low coefficient of thermal expansion. Unique properties like shape memory and excellent machinability make these materials special. Inconel 718 is an example and can be 3D printed.

- Cobalt Superalloy: Cobalt-based superalloys offer higher melting points compared to nickel- or iron-based counterparts. They also offer excellent hot corrosion resistance in comparison to nickel- or iron-based alloys. Cobalt-based superalloys are highly weldable compared to nickel-based alloys. Cobalt chrome powders can be 3D printed.

- Iron Superalloy: Iron-based superalloys offer high strength at regular room temperature and are highly resistant to oxidation, creep, wear and corrosion. They are much cheaper than the above two.

Aluminium

Aluminium has a high affinity to oxygen, thus forming a passive oxide layer which makes it corrosion proof. Most grades of aluminium are chemically resistant but grades 1xxx, 3xxx and 5xxx are the most resilient. They are tough in the pH range of 4.5 to 8.5 which is the general corrosive region. Anodising is a great way to add an anti-corrosion layer to normal aluminium.

- 1xxx Series: This grade is super pure (about 99%) and has the best corrosion resistance in normal applications.

- 3xxx Series: Manganese is the main alloying element in the 3xxx series (Al-Mn alloys - up to 1.25% Mn) is the main alloying element in this series. That makes it slightly less resilient against corrosion compared to 1xxx aluminium. On the other hand, Manganese makes the alloy ductile. Aluminium Al-Si1Mg for instance has high-stress corrosion cracking resistance.

- 5xxx Series: Main alloying element in this type of aluminium is magnesium and has almost a similar corrosion resistance as 3xxx grade aluminium. It offers a high rate of work hardening and high corrosion resistance. It also offers a bright surface finish.

Copper Alloys

Copper alloys have high thermal conductivity, corrosion resistance, excellent hardness, and offer high-temperature strength. Copper offers good resistance against corrosion and is also included in other metal alloys to improve the respective corrosion resistance. The most common corrosion-resistant metals in the copper alloy family are:

- Bronze: One of the oldest known materials is bronze. Modern bronze is 88% copper and 12% tin. Bronze may also contain nickel, manganese, aluminium, silicon, zinc or arsenic. The small amounts of silicon added to the alloy improve the corrosion resistance.

- Brass: Brasses are alloys of copper and zinc. They may also contain small amounts of tin to impart extra corrosion resistant properties whereas zinc may decrease the same. Brasses usually have high corrosion resistance and good tensile strength and have a lower melting point than bronze or even pure copper.

Titanium

Titanium is a highly durable metal and is used widely for engineering applications because this metal is corrosion-resistant and has a good strength to weight ratio. It is 40% lighter than steel, yet as strong as high strength steel.

Like other corrosion resistant metal materials, titanium also forms passive oxides without which it corrodes immediately. Titanium’s unique property is its resistance against chlorine. Titanium 3.7164 (Titan Grade 5) is a good example of corrosion-resistant material.

Comparing costs of parts productions using corrosion resistant materials

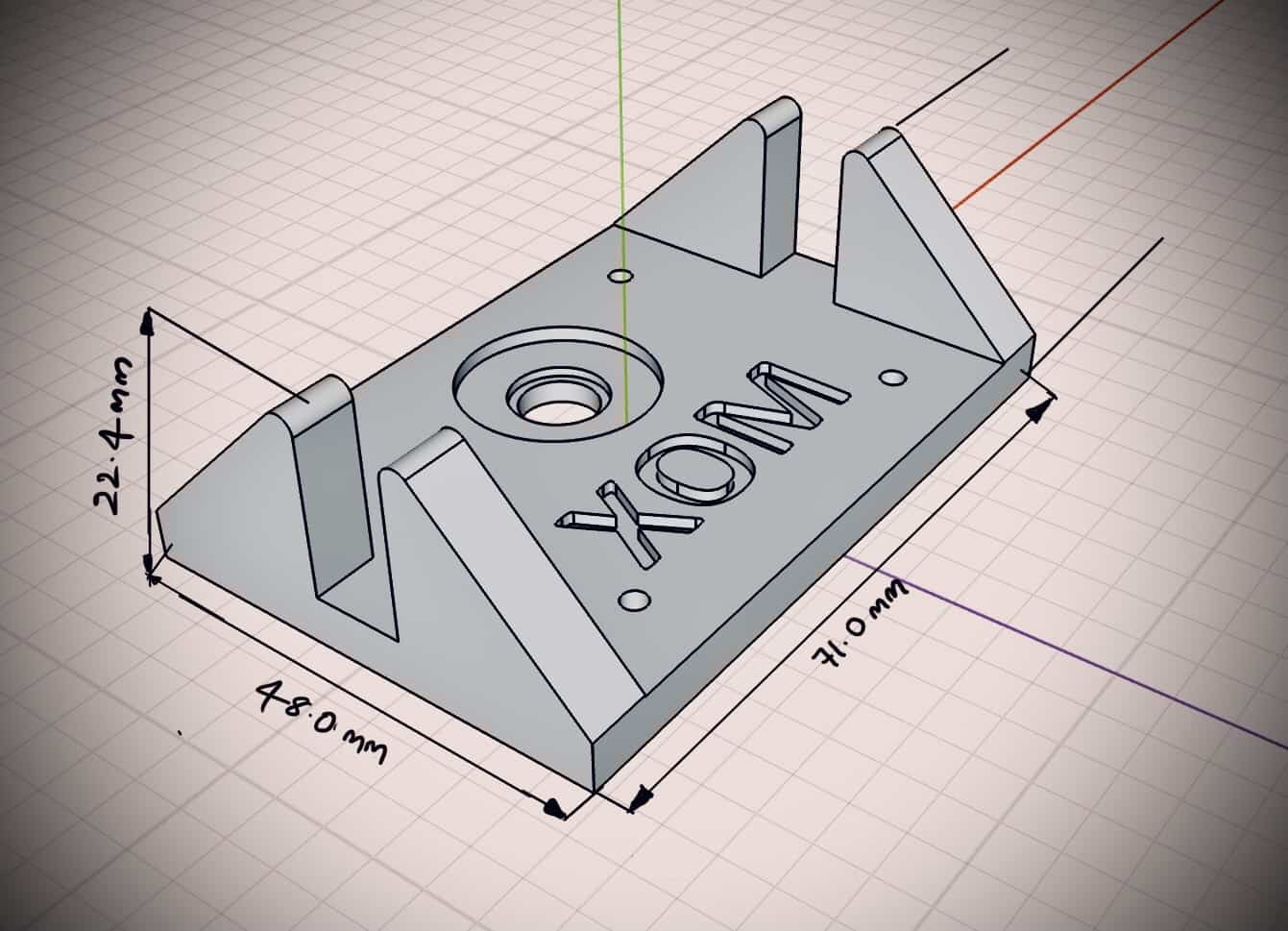

Let’s have a cost comparison of the production of parts using different corrosion resistant metal materials from Xometry’s Instant Quote Engine:

| Material | Manufacturing process | Cost per one unit | Unit cost per 10 pieces | Unit cost per 100 pieces |

| Stainless Steel 304 / 1.4301 | CNC | € 211.61 | € 66.41 | € 23.74 |

| Stainless Steel 316L / 1.4404 | CNC | € 228.58 | € 72.75 | € 25.68 |

| Stainless Steel 316L / 1.4404 | DMLS | € 387.12 | € 294.83 | Price on demand |

| Aluminium AlSi10mg | CNC | € 123.07 | € 35.35 | € 13.88 |

| Aluminium AlSi10mg | DMLS | € 174.76 | € 89.19 | € 87.80 |

| Titanium, T6Al4V | CNC | € 705.35 | € 215.06 | € 55.12 |

| Titanium, T6Al4V | DMLS | € 387.12 | € 294.83 | Price on demand |

| Inconel 718 | DMLS | € 487.77 | € 333.16 | Price on demand |

| Cobalt Alloy, CoCr | DMLS | € 522.61 | € 619.15 | Price on demand |

Way 2: Improve parts’ resistance to corrosion with post-processing treatments

The corrosion resistance of CNC machined, sheet metal and 3D printed parts can also be improved thanks to various surface finishing options:

- Anodising: A metal on machining, (mainly aluminium parts) uses oxidation processing to harden the surface of the part to resist wear.

- Spray paint processing: The spray paint prevents the part from rust, such as daily necessities, electrical enclosures, pipes, etc.

- Electroplating: The surface of the part is coated with other non-corrosive metal to avoid corrosion. Sometimes the below mentioned corrosion resistant metals are coated on normal metals to increase their life.

- Surface polishing: The surface burr processing is performed on CNC machined parts in order to cut the sharp burrs that are produced as a result of the machining. It is advised to polish the sharp part of the corner into a smooth face so that it will not cause harm to the human body during use.

Conclusion

Xometry Asia offers CNC machining and metal 3D printing services online, for on-demand 3D printing projects, for both prototypes and large batches. With a network of more than 10,000 partners worldwide, Xometry is able to deliver 3D printing parts in up to 3 days. Upload your CAD files to Xometry Instant Quoting Engine to get an instant quote with various manufacturing options available for CNC machining and DMLS 3D printing.