- Industry: Die casting and plastics industry

- Manufacturing process used: Selective Laser Sintering (SLS) 3D Printing

- Challenge: How to effectively showcase FIMRO’s large systems at trade fairs

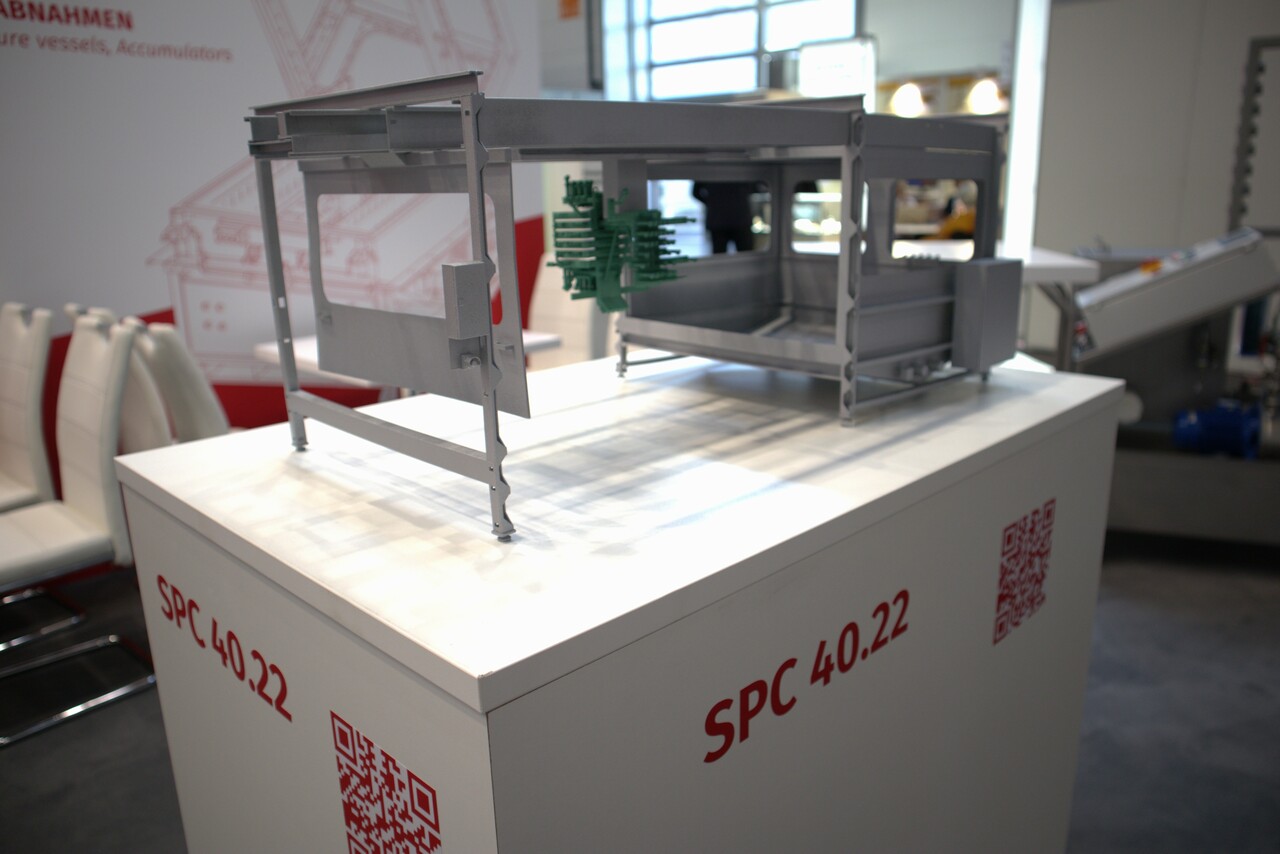

- Solution: Precise and cost-efficient production of a miniature model enabled the functionality and innovation of a cleaning system from FIMRO to be clearly demonstrated

Since 1995, FIMRO has been an established partner for peripheral equipment in the die casting and plastics industry. The company was founded by Rudolf Fitze and Bernd Mrochen as a 2-man business and has gradually become a family business over the years. FIMRO offers technical advice, sales, commissioning and service as a comprehensive package and constantly seeks to provide its customers with innovative solutions.

More recently, Matthias Mrochen has taken over the running of the company and expanded the area of systems engineering. FIMRO creates both the electrical designs and the mechanical designs itself and can thus adapt the standard systems to the respective customer requirements.

How to effectively showcase FIMRO’s large systems at trade fairs

FIMRO had the challenge of presenting innovative products at trade fairs while taking into account the size of its systems. The cleaning systems for spraying tools developed by FIMRO are large and unsuitable for displaying at trade fairs. This meant that FIMRO needed a way to display these systems on a small scale to be able to demonstrate the functionality and innovation of their products. Conventional production of these miniature models was not feasible due to the costs and effort involved.

3D-printed system with a scale of 1:10

To find a quick and cost-effective solution, FIMRO decided to get help from Xometry. Through Xometry, FIMRO discovered that it could 3D print models of its systems at the desired scale of 1:10. Using Xometry’s user-friendly platform (Xometry Instant Quoting Engine®), FIMRO was able to upload its models directly and get quotes quickly with corresponding delivery times. “We are at a lot of trade fairs and the problem is that our systems are rather large. The scaled-down version we have printed with Xometry – with a scale of about 1:10 – is usually around 7 meters long. So it would be quite time-consuming and expensive to present the standard size at trade fairs,” says Mrochen.

Bespoke advice proved decisive

To ensure that the miniature models met the requirements, an employee from FIMRO visited Xometry in person. This also gave them an opportunity to discuss material selection, stability, and colouring. The bespoke advice and the option to receive samples were decisive factors in FIMRO choosing to work with Xometry.

Results that speak for themselves

Xometry enabled FIMRO to have its cleaning equipment printed on the desired scale and to showcase it effectively at trade fairs. The trade fair model consists of several parts, all of which were produced using the SLS (selective laser sintering) 3D printing process. The parts are made of nylon PA12 grey/white and have a standard surface finish.

The miniature models were manufactured using precise and cost-efficient techniques. They have allowed FIMRO to clearly demonstrate the functionality and innovation of its products without having to transport the large original equipment, thus creating new opportunities to showcase their technologies worldwide.

The scale parts add authenticity and detail to the exhibit, giving customers and prospects realistic insight into FIMRO’s products. Xometry’s quick completion of the project has contributed to FIMRO’s successful trade fair appearances and to convincing potential customers of their innovative solutions.

What does the future hold for FIMRO?

Mrochen reports: “Now it would be amazing if we could take our other systems to trade fairs as small models in the car boot! It’s great to be able to do this and certainly very appealing for lots of companies to get large machines manufactured on a small scale. It means you can actually get a feel for these machines and systems—not just digitally on a screen.”

In addition, this experience will help FIMRO develop innovative solutions with Xometry in the future. FIMRO also plans to further explore potential use cases for 3D printing and expand its partnership with Xometry to realise the full potential of prototyping and low-volume production.

Working with Xometry has helped FIMRO improve how it showcases its products and open up new avenues for marketing its products. The confidence FIMRO now has in Xometry’s quality and reliability is expected to lead to a long-term partnership that will benefit both parties and enable innovative solutions for the industry.