Materials

Aluminium;Steel;Stainless steel;Copper;Titanium;Polymer;Nylon ;PC .All these materials are available in the Xometry Instant Quoting Engine. If you require a different, material please specify it as custom when you make a request.

Aluminium 3.4365

Alternative Designations: EN-AW7075 | Al-Zn6MgCu

Aluminium 3.4365/EN-AW7075 has high strength (57MPa), toughness and excellent resistance to fatigue. It has very good machinability.

Aluminium 3.3211

Alternative Designations: EN-AW6061 | Al-Mg1SiCu

Aluminium 3.3211/EN-AW6061 contains magnesium and silicon as its major alloying elements with trace amounts of copper.

Aluminium 3.3206

Alternative Designations: EN-AW6060 | Al-MgSi

Aluminium 3.3206/EN-AW6060 has good resistance to corrosion, good weldability and very suitable for cold forming.

Aluminium 3.2315

Alternative Designations: EN-AW6082 | Al-Si1Mg

Typically formed by rolling and extrusion, Aluminium 3.2315 has medium strength with very good weldability and thermal conductivity.

Aluminium 3.1645

Alternative Designations: EN AW–2007 | 3.1645 | AlCuMgPb

Aluminium 3.1645 is a short chipped aluminum alloy containing between 4.0 – 5.0% copper. It is very suitable for high machining speeds.

Steel 1.0570

Alternative Designations: St52-3

Compared to other carbon steels, Steel 1.0570 has high electrical conductivity but low thermal conductivity and low ductility.

Steel 1.0503

Alternative Designations: AF65C45

Steel 1.0503 (C45) has low thermal conductivity and low ductility among wrought carbon steels. It has a high tensile strength of 630MPa.

Steel 1.7225

Alternative Designations: 42CrMo4

Steel 1.7225 has high strength, toughness, good hardenability and resistance to impact. It is widely used in the construction of machines

Steel 1.7131

Alternative Designations: 16MnCr5

Steel 1.7131 has high surface hardness and wear resistance with good machinability. It is ideal for machine components.

Steel 1.0038

Alternative Designations: EN 10025 | S235JR

Steel 1.0038 can be formed into many products. Its excellent weldability makes it to be widely used in bridges, transmission towers etc.

Stainless Steel 1.4571

Alternative Designations: X6CrNiMoTi17-12-2

Stainless Steel 1.4571 contains a small amount of titanium (about 0.5%). It has good machinability but cannot be hardened by heat treatment.

Stainless Steel 1.4404

Alternative Designations: 316L | X2CrNiMo17-12-2

The addition of molybdenum results in improved corrosion resistance with good stability against chloric and non oxidizing acid.

Stainless Steel 1.4301

Alternative Designations: X5CrNi18.10

Stainless steel 1.4301 is chromium-nickel austenitic stainless steel. The chromium element gives it excellent corrosion resistance.

Copper 2.0065

Alternative Designations: E-Cu58Ms58

Copper 2.0065 has high electrical conductivity. Its good machinability makes it easy to shape into different forms.

Copper 2.0060

Alternative Designations: Cu-ETP

Copper 2.0060 has high conductivity and high corrosion resistance. It has a tensile strength of 360MPa. It has excellent machinability.

Brass 2.0401

Alternative Designations: CuZn39Pb3

Brass 2.0401 has excellent hot formability and can easily be soldered or brazed. It has very good free-cutting.

Titanium 3.7164

Alternative Designations: Titan Grade 5 | 6Al-4V9

Titanium 3.7164 has exceptional strength compared to pure titanium but retains the same stiffness and thermal properties.

Titanium 3.7035

Alternative Designations: Titan Grade 2

Titanium 3.7035 has excellent strength-to-weight ratio with good resistance to corrosion. Its thermal stresses are low.

UHMW PE

Alternative Designations: Ultra high molecular weight polyethylene

UHMW PE is extremely tough and has high resistance to abrasion and wear. It is corrosion resistant and self-lubricating.

PTFE

Alternative Designations: Teflon

PTFE (Teflon) is a highly slippery material with excellent resistance to extreme temperatures. It has outstanding insulating properties.

POM

Alternative Designations: Delrin, Acetal

POM is an easy resin for molding. It has a relatively high tensile strength as well as high resistance to wear, creep and warp.

Acrylic

Alternative Designations: PMMA

Acrylic (PMMA) is the most common form of clear, moldable thermoplastic, often used in place of glass due to its higher resistance.

PEEK

Alternative Designations: Polyetheretherketone

PEEK is used in the production of components such as tubes, bearings, seals, valves, electric insulation and even medical implants.

PC

Alternative Designations: Polycarbonate

PC – Polycarbonate is a naturally transparent plastic with high strength and durability on impact. It is shatter resistant and heat resistant.

ABS

Alternative Designations: Acrylonitrile Butadiene Styrene

ABS (Acrylonitrile Butadiene Styrene) is a thermoplastic material widely known for its high resistance to impact and toughness.

Nylon PA 12 Glass-Filled (SLS)

Alternative Designations: PA12GB

This is a whitish polyamide 12 powder that is glass filled. Its stiffness is excellent and it has good elongation at break.

Nylon PA 12 Food Grade Whitish

Alternative Designations: Food Grade SLS PA12 Whitish

This material produces functional parts of the highest quality. It has a well-balanced property profile with excellent constant behaviour.

Nylon PA 12 Alumide Grey

Alternative Designations: PA12 Alumide Grey / MJF PA12CB

This material is a metallic grey polyamide powder filled with aluminium. It has high stiffness and good post processing abilities.

Nylon PA 12 (SLS)

Alternative Designations: Polyamide 12

Nylon produces parts with long-term durability that is similar to that of standard plastic parts. Excellent stability for a long time.

Nylon PA 11 Food Grade

Alternative Designations: PA11 BLUE – Food grade

This material produces parts with blue colour. It consists of a food compliant PA11 powder. It is often applied in the production of nozzles.

Carbon Fiber Reinforced Polyamide 12

Alternative Designations:

This fibre composite material is made from the PA12 thermoplastic with approximately 35% carbon fibre about 0.15mm fibre length.

ABS M30

Alternative Designations: Acrylonitrile butadiene styrene M30

ABS M30 is a high impact resistant and tough material: it has a glass transition temperature of about 105°C.

PP

Alternative Designations: Polypropylene

PP (Polypropylene) has excellent resistance to moisture and chemicals, impressive impact strength and good elasticity.

CE 221

Alternative Designations: Cyanate ester

CE 221 has long-term thermal stability with glass transition temperature of about 225°C. It has a tensile strength of 92MPA.

UMA 90

Alternative Designations: Urethane Methacrylate

UMA 90 produces smooth surface finish with excellent mechanical properties. It has high stiffness and strength.

DPR 10

Alternative Designations: Digital Production Resin

DPR 10 offers high accuracy and quick printability, and its rigidity makes it suitable for models and dies.

EPX 82

Alternative Designations: Epoxy

EPX 82 has an excellent blend of toughness, stiffness, temperature resistance and high tensile strength of 82MPa.

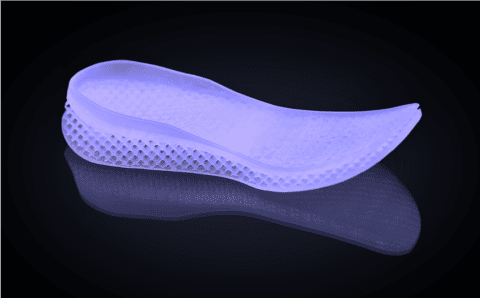

FPU 50

Alternative Designations: Flexible Polyurethane

FPU 50 is robust and semi-rigid. It is suitable for applications that require toughness to withstand repetitive loading.

RPU 70

Alternative Designations: Rigid Polyurethane

RPU 70 is a stiff material with high strength. It has moderate resistance to heat with heat deflection temperature of 60°C.

Xtreme White 200 Polypropylene

Alternative Designations: Accura Xtreme White 200

Xtreme White 200 Polypropylene has high elongation at break, high impact strength with excellent toughness. It is stiff and durable.

Xtreme Grey Polypropylene

Alternative Designations: Accura Xtreme Grey

Xtreme Grey Polypropylene has excellent toughness and is resistant to breakage. It is ideal for snap fits used in electronic products.

Watershed XC 11122 ABS/PBT – Like

Alternative Designations:

Watershed XC is a low viscous material that produces parts that are strong, tough, water-resistant and most importantly, nearly colourless.

ULTEM 9085

Alternative Designations:

ULTEM 9085 has a high strength – to – weight ratio, high impact strength with good heat resistance. It is highly flame retardant.

ULTEM 1010

Alternative Designations:

ULTEM 1010 has the highest heat resistance, chemical resistance and tensile strength compared to other FDM thermoplastics.

PEEK

Alternative Designations: Polyetheretherketone

PEEK is used in the production of components such as tubes, bearings, seals, valves, electric insulation and even medical implants.

PETG

Alternative Designations:

PETG has significant chemical resistance, durability and good formability. It has low forming temperatures making it popular in consumer applications.

PLA

Alternative Designations: Polyactic Acid

PLA is derived from renewable sources and is biodegradable. It can easily be melted and shaped without losing its mechanical properties.

PC

Alternative Designations: Polycarbonate

PC – Polycarbonate is a naturally transparent plastic with high strength and durability on impact. It is shatter resistant and heat resistant.

PC – Like Heat Resist Translucent

Alternative Designations: Accura 48

PC – Like Heat Resist Translucent is best suited for parts that require high strength and stiffness with high temperature resistance.

PC – ABS

Alternative Designations: PC – ABS Polycarbonate

PC – ABS Polycarbonate blends the ease of processing of ABS with the high strength and mechanical properties of PC.

Nylon PA 12 Carbon-Filled

Alternative Designations:

The blend of Nylon 12 resin with chopped carbon fibre gives this material excellent structural properties.

Nylon PA 12 Glass-Filled (MJF)

Alternative Designations:

Compared to the Nylon PA12, this has enhanced compressive strength with improved heat distortion temperature.

Nylon PA 11

Alternative Designations:

Nylon PA11 material is highly impact resistant with a shore hardness of 80. It is 100% biocompatible with up to 70% reusability.

ASA

Alternative Designations: Acrylonitrile Styrene Acrylate

ASA (Acrylonitrile Styrene Acrylate) is an amorphous thermoplastic with improved weather resistance. It is widely used in prototyping in 3D printing.

ABS SL 7820

Alternative Designations:

With a black appearance, ABS SL 7820 is rigid and tough. It allows for accurate and robust build with good surface finish and detail.

ABS

Alternative Designations: Acrylonitrile Butadiene Styrene

ABS (Acrylonitrile Butadiene Styrene) is a thermoplastic material widely known for its high resistance to impact and toughness.

ABS ESD7

Alternative Designations:

ABS ESD7 is a durable thermoplastic with electrostatic-dissipative properties. It is widely applied in the manufacturing of jigs and fixtures for electronic components.

Nylon PA 12 (FDM)

Alternative Designations: Nylon 12 | Polyamide 12

Nylon PA 12 is one of the most popular 3D printing materials. It has good mechanical properties such as toughness and strength.

Flex Whitish

Alternative Designations: Flex TPU/TPE-like

This material is a powder of a thermoplastic elastomer that is naturally coloured and rubber like. It produces fully functional parts.

Estane 3D TPU M95A

Alternative Designations:

Estane 3D TPU M95A has easy and quick printability. It is used in manufacturing projects that require both rubber and plastic properties.

EPU 40

Alternative Designations: Elastic Polyurethane

EPU 40 is useful for ornaments and mechanical parts. It has high elastic behaviour under both tensile and compressive stress.

SIL 30

Alternative Designations:

SIL 30 is biocompatible as well as tear resistant. It provides comfortable skin contact. It is used in the printing of wearables.

True Silicone

Alternative Designations:

True silicone has a high resolution, an excellent surface finish, and is resistant to acids, bases and non-polar solvents.

Tool Steel MS1

Alternative Designations: 1.2709

Tool Steel MS1 is a high wear resistant material with ultra-high strength and is easily machinable. It has enhanced ductility.

Stainless Steel 17.4

Alternative Designations:

Stainless Steel 17.4 is a chromium-nickel copper steel with high strength and excellent toughness. It has a tensile strength of 1070N/mm2.

Aluminium 1706

Alternative Designations: EN - 1706 | AlSiMG

Aluminium 1706 has excellent strength at elevated temperatures (about 200°C). It has good resistance to corrosion and can be polished easily.

Stainless Steel 1.4404

Alternative Designations: 316L | X2CrNiMo17-12-2

The addition of molybdenum results in improved corrosion resistance with good stability against chloric and non oxidizing acid.

Inconel 718

Alternative Designations:

Inconel 718 a nickel-chromium based high strength super alloy. It is resistant to corrosion and extreme pressure.

TAURUS(黑色)

Alternative Designations: 高强度耐高温光敏树脂

进口Somos Taurus材料,高韧性耐高温90℃,固化之后强度比ABS好一点,热性能和强度优良。

Rigid Photopolymer

Alternative Designations: Rigid Opaque Material

Opaque materials are good material choices for light functional testing, patterns, and prototypes. This material gives brilliant colour.

Aluminium 3.2315

Alternative Designations: EN-AW6082 | Al-Si1Mg

Typically formed by rolling and extrusion, Aluminium 3.2315 has medium strength with very good weldability and thermal conductivity.

Aluminium 3.3547

Alternative Designations: EN AW-5083 | Al-Mg4,5Mn

Aluminium 3.3547 / EN AW-5083 is a rolled plate with moderate strength. It is widely used in the capital goods industry.

Steel 1.0570

Alternative Designations: St52-3

Compared to other carbon steels, Steel 1.0570 has high electrical conductivity but low thermal conductivity and low ductility.

Steel 1.0038

Alternative Designations: EN 10025 | S235JR

Steel 1.0038 can be formed into many products. Its excellent weldability makes it to be widely used in bridges, transmission towers etc.

Stainless Steel 1.4404

Alternative Designations: 316L | X2CrNiMo17-12-2

The addition of molybdenum results in improved corrosion resistance with good stability against chloric and non oxidizing acid.

Stainless Steel 1.4301

Alternative Designations: X5CrNi18.10

Stainless steel 1.4301 is chromium-nickel austenitic stainless steel. The chromium element gives it excellent corrosion resistance.

PSU

Alternative Designations: Polysulfone

PSU (Polysulfone) is a transparent material. It is tough and rigid with good thermal stability and resistance to chemicals.

PPS

Alternative Designations: Polyphenylene Sulphide

PPS has excellent strength of 80MPa and is highly rigid. It is resistant to high temperature, UV light, chemicals and creep.

PPE – PS

Alternative Designations: Polyphenylene ether – Polystyrene

PPE – PS is a blend of polyphenylene ether and polystyrene. It is highly ductile and exhibits good resistance to impact.

PS

Alternative Designations: Polystyrene

PS (Polystyrene) is a transparent, amorphous thermoplastic. It is hard, brittle, rigid and resistant to gamma radiation.

PP

Alternative Designations: Polypropylene

PP (Polypropylene) has excellent resistance to moisture and chemicals, impressive impact strength and good elasticity.

PE

Alternative Designations: Polyethylene

PE (Polyethylene) has good strength ratio. It is resistant to chemicals, impermeable and exhibits good electrical insulation properties.

PET

Alternative Designations: Polyethylene terephthalate

PET has a melting point of about 270°C; hence, molding is done at a high temperature. It is a hard material with low moisture absorption.

PEI

Alternative Designations: Ultem

With a strong environmental resistance, PEI is highly stiff and stable. It is rigid and retains its strength at high temperatures.

PC – PBT

Alternative Designations: Polycarbonate-Polybutylene Terephthalate

PC – PBT has high toughness, dimensional stability and good resistance to heat and chemicals. It has good impact resistance and stiffness.

PBT

Alternative Designations: Polybutylene terephthalate

PBT has excellent resistance to abrasion and creep. It has a low coefficient of friction and a low moisture absorption.

Nylon PA 6/6

Alternative Designations: Polyamide 6/6 | Nylon 6/6

PA 6/6 is the most common variant of nylon used for engineering applications. It has a high melting temperature.

Nylon PA 6

Alternative Designations: Polyamide 6 | Nylon 6

The fibers are tough but retain high tensile strength and elasticity. PA 6 is extremely resistant to wear and good electrical insulation.

LDPE

Alternative Designations: Low Density Polyethylene

LDPE is the most flexible member of the polyethylene family. It offers good resistance to stress and pliability with good strength.

HDPE

Alternative Designations: High Density Polyethylene

HDPE is light in weight with high strength. It is resistant to chemicals and heat, impermeable and has good electrical insulation.

POM

Alternative Designations: Delrin, Acetal

POM is an easy resin for molding. It has a relatively high tensile strength as well as high resistance to wear, creep and warp.

Acrylic

Alternative Designations: PMMA

Acrylic (PMMA) is the most common form of clear, moldable thermoplastic, often used in place of glass due to its higher resistance.

PEEK

Alternative Designations: Polyetheretherketone

PEEK is used in the production of components such as tubes, bearings, seals, valves, electric insulation and even medical implants.

PLA

Alternative Designations: Polyactic Acid

PLA is derived from renewable sources and is biodegradable. It can easily be melted and shaped without losing its mechanical properties.

PC

Alternative Designations: Polycarbonate

PC – Polycarbonate is a naturally transparent plastic with high strength and durability on impact. It is shatter resistant and heat resistant.

PC – ABS

Alternative Designations: PC – ABS Polycarbonate

PC – ABS Polycarbonate blends the ease of processing of ABS with the high strength and mechanical properties of PC.

ASA

Alternative Designations: Acrylonitrile Styrene Acrylate

ASA (Acrylonitrile Styrene Acrylate) is an amorphous thermoplastic with improved weather resistance. It is widely used in prototyping in 3D printing.

ABS

Alternative Designations: Acrylonitrile Butadiene Styrene

ABS (Acrylonitrile Butadiene Styrene) is a thermoplastic material widely known for its high resistance to impact and toughness.

TPE

Alternative Designations: Elastomer

TPE (Elastomer) exhibits excellent resistance to flexural fatigue. It has high impact strength and excellent chemical resistance.

PVC

Alternative Designations: Polyvinyl chloride

PVC (Polyvinyl chloride) is the third most synthesized thermoplastic material. It is resistant to weathering, chemicals, corrosion and shock.

Aluminium ADC12

Alternative Designations: AlSi11Cu3

The ADC12 aluminium is more often used as an alternative for the A380 aluminium for parts that are highly intricate.

Aluminium A380

Alternative Designations: AlSi8Cu3

The A380 Aluminium gives an excellent combination of machinability, heat transfer and easy casting together with other properties.