The surface finish of a 3D printed part is determined by the material the part is made of, as well as the 3D printing technology used. Because there are various 3D printing materials and 3D printing technologies, customers often wonder what the surface finish of their ordered part would be, and what the part will look like.

In this article, we will go through MJF and SLS 3D printing technologies, the printable materials using these technologies, and their resulting surface finishes.

Comparative table: SLS and HP MJF 3D printing materials

| Printing technology | Material | Surface finish | Examples |

| SLS | Nylon PA 12 | Grainy (can be improved to satin-like matte via media tumbling) |  Standard – SLS 3D Printing |

| Nylon PA 12 GB/GF | Grainy (can be improved to satin-like matte via media tumbling) |  Glass-Filled – 3D Printing | |

| HP MJF | Nylon PA 12 | Grainy |  Standard – HP MJF 3D Printing |

| Nylon PA 11 | Grainy but smoother than Nylon PA 12 |  Media Tumbled Nylon PA 11 – HP MJF (www.hp.com) | |

| Nylon PA 12 GB/GF | Grainy |  Media Tumbled and Glass Filled Nylon PA 12 – HP MJF (www.hp.com) | |

| Estane 3D TPU M95A | Smooth rubber-like feel |  Media Tumbled Estane 3D TPU M95A – HP MJF (www.hp.com) |

Selective Laser Sintering

SLS is a 3D printing technology in which a high-power laser, such as a carbon dioxide laser, fuses nylon powder to form an object. This process works by scanning cross-sections generated from a CAD model. Using these, the printer then sinters layer upon layer of powder until the part is formed. SLS printing generally produces a grainy surface finish. However, there might be slight variations in the surface finishes of different SLS printed materials. Below you can find the major materials for SLS printing and their surface finish, among other characteristics.

Nylon PA 12 (Grey, White, Full colour)

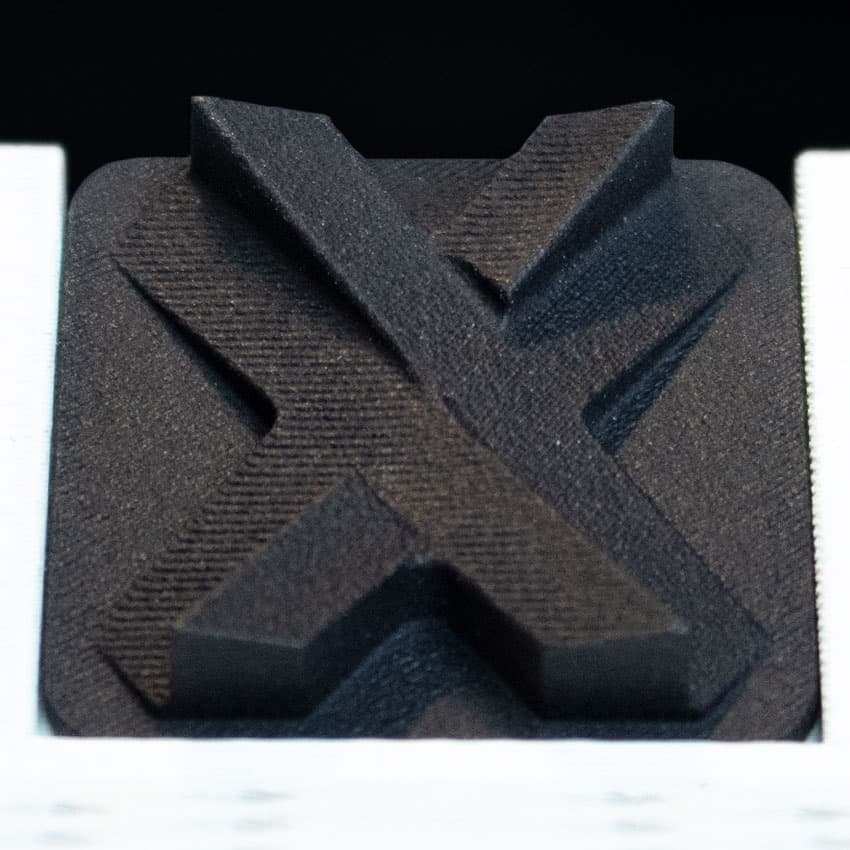

SLS printed Nylon PA 12 has all-round great mechanical properties. It is resistant to most inorganic chemicals including ammonia and sulfuric acid. It is also resistant to heat with a melting point of 178 - 180°C. The material is available in grey, white and has an option to be printed in full colour (literally, any color desired). As-printed, SLS printed Nylon PA 12 has a granular surface finish. After media tumbling, this is improved to a satin-like matte. The printed parts can be dyed to any desired colour.

Nylon PA 12 GB/GF

This is a modified variant of Nylon PA 12 that has been reinforced with glass beads to create parts with higher thermal stability and stiffness than standard Nylon PA 12. Nylon PA 12 GB/GF also has an as-printed grainy surface finish that becomes smoother after media tumbling.

HP Multi Jet Fusion

Multi Jet Fusion, also known as HP MJF, is a proprietary 3D technology owned by HP (Hewlett Packard). In this process, a thin layer of polymer is deposited on a building platform and a fusing agent is jetted onto this layer and another layer of polymer is deposited. Everything is sintered together by an infrared source. This process is repeated until the part is formed. The popular materials for MJF are as follows.

Nylon PA 12 (Grey, Full colour)

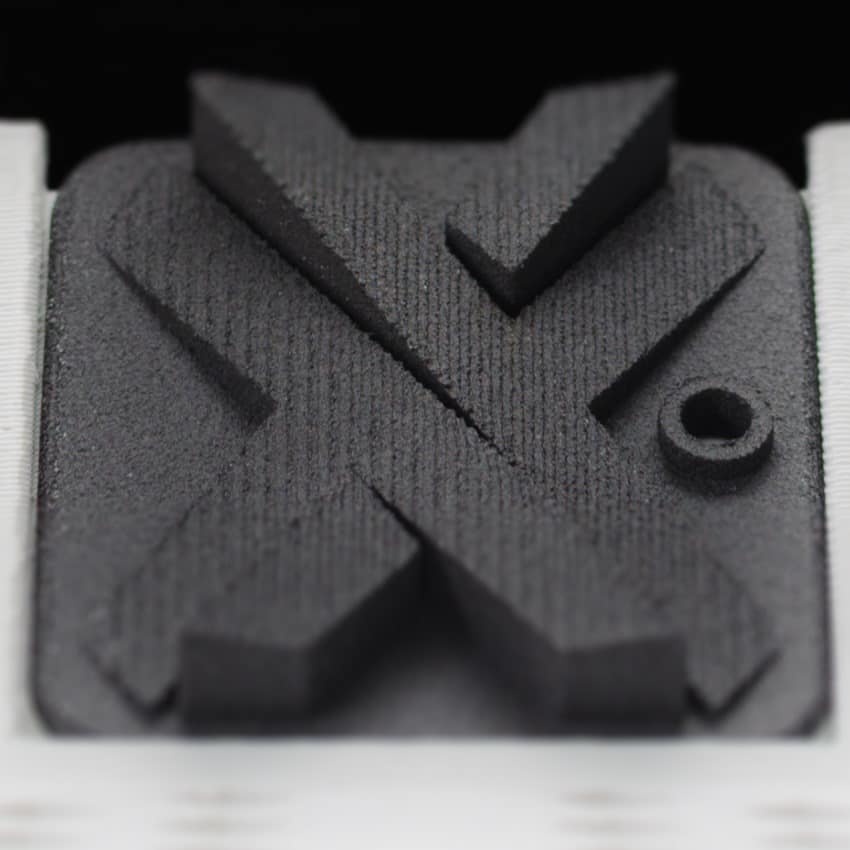

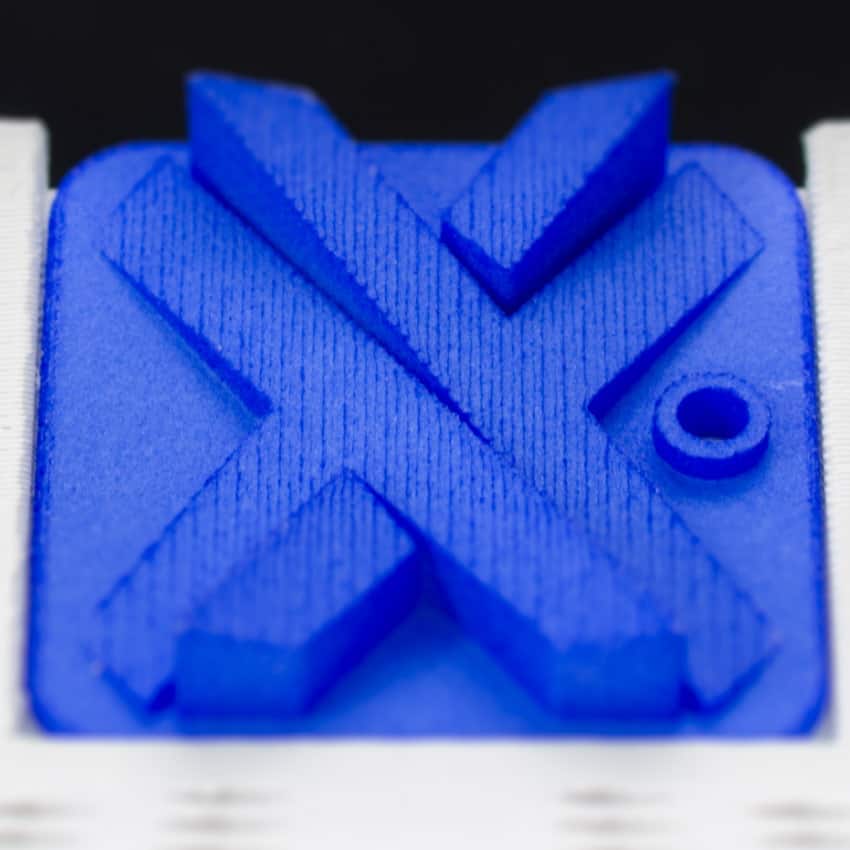

MJF printed Nylon 12 has slightly higher tensile strength and elongation at break than its SLS printed counterpart. This material has a grainy surface finish similar to a sugar cube. Media tumbling will make the surface smoother.

Nylon PA 12 GB/GF

MJF printed Nylon PA 12 GB is similar in surface finish to MJF printed standard Nylon PA 12. The material also has a grainy surface finish.

Nylon PA 11

Nylon PA 11 offers higher resistance to impact and ultraviolet rays but less strength and stiffness than Nylon PA 12. The surface finish is somewhat rough and grainy but smoother than Nylon PA 12.

Estane 3D TPU M95A

TPU is an elastomer with high tear resistance and a shore hardness that is suitable for parts that require durability and rubber-like properties. MJF printed Estane 3D TPU M95A has a smooth rubber-like feel.

Conclusion

Xometry offers high-quality MJF and SLS printing for various materials including Nylon PA 11, Nylon PA 12, Nylon PA 12 GB/GF. Head over to our instant quoting platform to get a quote for your 3D printed parts.

To learn more about the materials and their surface finish, check out the video below: